loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 12, 2025 18:30

Back to list

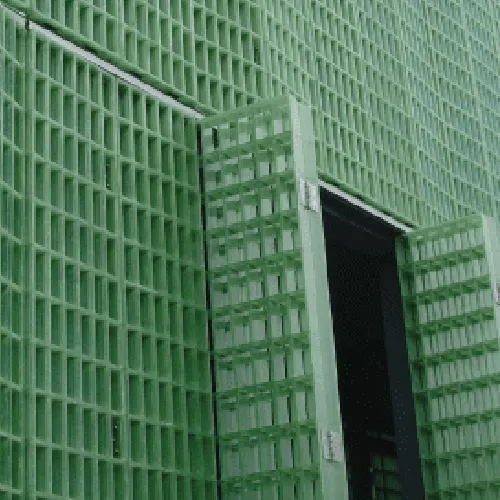

heavy duty drain grating

Heavy-duty drain grating is an essential component in a range of environments, from industrial facilities to public infrastructure projects. Its primary function is to allow for efficient drainage while ensuring safety and durability under heavy loads. This article delves into the benefits, applications, and key considerations when selecting heavy-duty drain grates, providing a comprehensive understanding of their role in various settings.

Installation and maintenance are additional factors where expertise is crucial. Proper installation requires advanced knowledge of environmental conditions and substrate characteristics to optimize drainage performance and structural stability. Moreover, routine checks and maintenance are vital in prolonging the lifespan of the gratings. Regular maintenance includes clearing blockages, inspecting for damage, and applying protective coatings if necessary to prevent rust and degradation. The authority on heavy-duty drain grates can also be observed through compliance with safety and environmental regulations. Manufacturers and suppliers who adhere to rigorous quality standards during their production processes ensure that their products are dependable and meet legal requirements. This compliance extends the trustworthiness of the product, providing assurance that the grating will perform as needed in critical situations. The versatility of heavy-duty drain grates is evident across various industry sectors. In urban infrastructure, for instance, these grates play a vital role in effective stormwater management, preventing flooding and protecting roadway surfaces. In transportation hubs like railways and airports, the reliability of these grates is crucial not only for water management but also for ensuring the safety of passengers and equipment. For stakeholders, including civil engineers, facility managers, and contractors, choosing a heavy-duty drain grating system involves strategic consideration of the specific needs of the site, including load requirements, environmental exposure, and maintenance capabilities. Trust in the products selected is fortified by choosing suppliers with a track record of excellence, transparency in material sourcing, and commitment to sustainable practices. In conclusion, heavy-duty drain grating stands as a pivotal element in both industrial and public infrastructure, offering unparalleled durability and functionality. By understanding the critical factors of material, design, load classification, and maintenance, stakeholders can ensure the effective and reliable management of drainage, significantly enhancing the safety and longevity of the installations. Investing in high-quality grating systems is a decision that pays long-term dividends in performance and peace of mind.

Installation and maintenance are additional factors where expertise is crucial. Proper installation requires advanced knowledge of environmental conditions and substrate characteristics to optimize drainage performance and structural stability. Moreover, routine checks and maintenance are vital in prolonging the lifespan of the gratings. Regular maintenance includes clearing blockages, inspecting for damage, and applying protective coatings if necessary to prevent rust and degradation. The authority on heavy-duty drain grates can also be observed through compliance with safety and environmental regulations. Manufacturers and suppliers who adhere to rigorous quality standards during their production processes ensure that their products are dependable and meet legal requirements. This compliance extends the trustworthiness of the product, providing assurance that the grating will perform as needed in critical situations. The versatility of heavy-duty drain grates is evident across various industry sectors. In urban infrastructure, for instance, these grates play a vital role in effective stormwater management, preventing flooding and protecting roadway surfaces. In transportation hubs like railways and airports, the reliability of these grates is crucial not only for water management but also for ensuring the safety of passengers and equipment. For stakeholders, including civil engineers, facility managers, and contractors, choosing a heavy-duty drain grating system involves strategic consideration of the specific needs of the site, including load requirements, environmental exposure, and maintenance capabilities. Trust in the products selected is fortified by choosing suppliers with a track record of excellence, transparency in material sourcing, and commitment to sustainable practices. In conclusion, heavy-duty drain grating stands as a pivotal element in both industrial and public infrastructure, offering unparalleled durability and functionality. By understanding the critical factors of material, design, load classification, and maintenance, stakeholders can ensure the effective and reliable management of drainage, significantly enhancing the safety and longevity of the installations. Investing in high-quality grating systems is a decision that pays long-term dividends in performance and peace of mind.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024