loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 08, 2025 04:30

Back to list

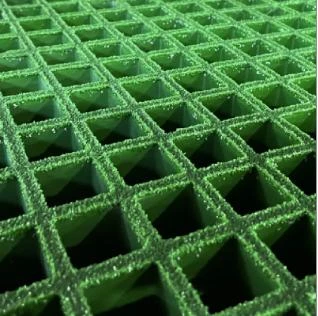

frp micro mesh grating

Heavy duty fiberglass grating stands out as a paramount choice for industries where durability, corrosion resistance, and safety are top priorities. Its unrivaled performance in challenging environments makes it an indispensable asset. With years of experience in materials engineering, I have seen firsthand the transformative potential of this formidable material. Let's delve into the essential characteristics and benefits of heavy duty fiberglass grating and its industry applications, drawing upon reliable expertise and authoritative insights.

Trust in heavy duty fiberglass grating is further amplified by its compliance with industry standards and rigorous testing. Reputable manufacturers adhere to ASTM standards, ensuring that their products meet the necessary criteria for performance and safety. This adherence not only guarantees quality but also instills confidence in engineers and procurement specialists tasked with selecting materials that align with stringent regulatory requirements. From an environmental perspective, fiberglass grating provides a sustainable alternative, given its longer lifespan and reduced need for replacement. This aspect mitigates the environmental impact associated with frequent material disposal and replenishment. As industries pivot towards eco-friendly practices, the inherent sustainability of fiberglass grating aligns with contemporary environmental objectives. In conclusion, heavy duty fiberglass grating emerges as an authoritative choice across diverse industries, thanks to its robust structural attributes, reliable safety features, and minimal maintenance demands. Its deployment in industrial sites is a testament to its enduring reliability and performance. By integrating this advanced material, organizations can achieve heightened safety, operational excellence, and notable cost efficiency, establishing a strong foundation for future growth and adaptability in a rapidly evolving industrial landscape.

Trust in heavy duty fiberglass grating is further amplified by its compliance with industry standards and rigorous testing. Reputable manufacturers adhere to ASTM standards, ensuring that their products meet the necessary criteria for performance and safety. This adherence not only guarantees quality but also instills confidence in engineers and procurement specialists tasked with selecting materials that align with stringent regulatory requirements. From an environmental perspective, fiberglass grating provides a sustainable alternative, given its longer lifespan and reduced need for replacement. This aspect mitigates the environmental impact associated with frequent material disposal and replenishment. As industries pivot towards eco-friendly practices, the inherent sustainability of fiberglass grating aligns with contemporary environmental objectives. In conclusion, heavy duty fiberglass grating emerges as an authoritative choice across diverse industries, thanks to its robust structural attributes, reliable safety features, and minimal maintenance demands. Its deployment in industrial sites is a testament to its enduring reliability and performance. By integrating this advanced material, organizations can achieve heightened safety, operational excellence, and notable cost efficiency, establishing a strong foundation for future growth and adaptability in a rapidly evolving industrial landscape.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024