loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 10, 2025 09:48

Back to list

frp micro mesh grating

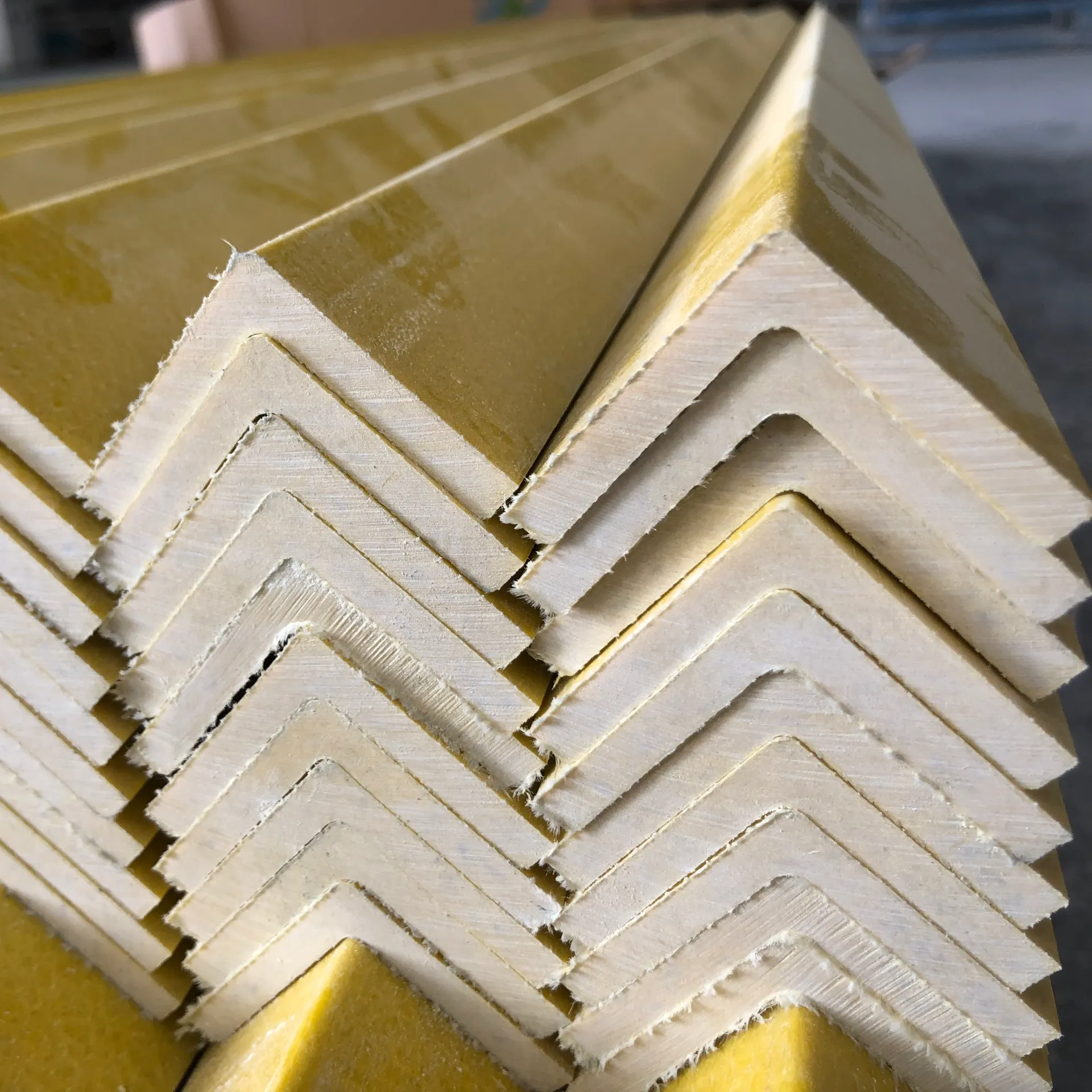

Heavy-duty FRP grating has emerged as an indispensable material in various industries due to its superior qualities and advantages over traditional materials such as steel and aluminum. Constructed from fiberglass reinforced plastic, these gratings exemplify durability, corrosion resistance, and lightweight attributes, making them ideal for a plethora of applications.

Trustworthiness is another critical factor contributing to the growing adoption of heavy-duty FRP grating. Companies specializing in FRP production have invested extensively in quality assurance processes to maintain high quality and dependability. This includes rigorous testing protocols before the gratings are shipped for installation. Many manufacturers offer warranties that underscore their confidence in the product's durability and performance, further solidifying their trust in the eyes of end-users. This commitment to quality assurance and customer satisfaction enhances the perceived dependability of FRP grating. Practical applications of FRP grating exemplify its utility and reliability across various sectors. In the offshore oil and gas industry, for instance, the material is prized for its anti-corrosive properties, ensuring safety and reliability in harsh marine environments. Similarly, pharmaceutical plants benefit from its chemical resistance and cleanliness, requirements essential for maintaining high standards of production and worker safety. The transportation sector, too, finds value in FRP’s lightweight properties, which contribute to fuel efficiency and ease of installation. Innovation within the FRP grating industry continues to push the boundaries of what these products can achieve. Developments in composite technology are leading to even stronger, lighter, and more durable gratings. Whether through incorporating advanced materials or refining manufacturing techniques, these innovations position FRP grating as not only a current staple but also a future-forward solution poised to meet evolving industry needs. In conclusion, heavy-duty FRP grating stands as a testament to modern material science's potential to provide efficient, reliable, and cost-effective solutions. Through authentic experiences and comprehensive expertise, it has been demonstrated that FRP grating surpasses traditional materials in several critical categories. Its authoritative recognition by industry standards, coupled with the inherent trustworthiness provided by manufacturers, makes it an excellent choice for industries seeking to enhance performance while reducing long-term costs. With ongoing innovation, the future of FRP grating looks promising, offering ever-better solutions to meet the demands of tomorrow's industrial landscapes.

Trustworthiness is another critical factor contributing to the growing adoption of heavy-duty FRP grating. Companies specializing in FRP production have invested extensively in quality assurance processes to maintain high quality and dependability. This includes rigorous testing protocols before the gratings are shipped for installation. Many manufacturers offer warranties that underscore their confidence in the product's durability and performance, further solidifying their trust in the eyes of end-users. This commitment to quality assurance and customer satisfaction enhances the perceived dependability of FRP grating. Practical applications of FRP grating exemplify its utility and reliability across various sectors. In the offshore oil and gas industry, for instance, the material is prized for its anti-corrosive properties, ensuring safety and reliability in harsh marine environments. Similarly, pharmaceutical plants benefit from its chemical resistance and cleanliness, requirements essential for maintaining high standards of production and worker safety. The transportation sector, too, finds value in FRP’s lightweight properties, which contribute to fuel efficiency and ease of installation. Innovation within the FRP grating industry continues to push the boundaries of what these products can achieve. Developments in composite technology are leading to even stronger, lighter, and more durable gratings. Whether through incorporating advanced materials or refining manufacturing techniques, these innovations position FRP grating as not only a current staple but also a future-forward solution poised to meet evolving industry needs. In conclusion, heavy-duty FRP grating stands as a testament to modern material science's potential to provide efficient, reliable, and cost-effective solutions. Through authentic experiences and comprehensive expertise, it has been demonstrated that FRP grating surpasses traditional materials in several critical categories. Its authoritative recognition by industry standards, coupled with the inherent trustworthiness provided by manufacturers, makes it an excellent choice for industries seeking to enhance performance while reducing long-term costs. With ongoing innovation, the future of FRP grating looks promising, offering ever-better solutions to meet the demands of tomorrow's industrial landscapes.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024