loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 21, 2025 05:18

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

Industrial Reverse Osmosis (RO) Water Systems Innovation in Hydration and Efficiency

Expertise is a critical component in the deployment of industrial RO systems. Their installation and upkeep require skilled personnel well-versed in the intricacies of reverse osmosis technology. Proper training and certification ensure that technical teams can optimize system performance, troubleshoot issues promptly, and implement necessary upgrades effectively. A continuous emphasis on skill development is essential to maintaining optimal functionality and making informed adjustments as technological advancements occur. The authoritativeness of industrial RO systems lies in their widespread adoption and endorsement by leading industry bodies and regulatory agencies. Health authorities recognize these systems' ability to produce water of unparalleled purity—a standard necessary in sensitive applications such as medical device manufacturing and biotechnology. Industrial RO systems also align with regulatory compliance for wastewater disposal, providing peace of mind to facility operators concerned with legislation adherence. Trustworthiness in industrial RO systems is built upon a legacy of proven results and innovations tailored to evolving industry needs. Manufacturers of these systems foster trust through rigorous quality assurance protocols, transparent production practices, and consistent customer support. Industry leaders often share testimonials and case studies illustrating RO systems’ transformative impact on their operations, further solidifying their credibility. Looking forward, the future of industrial RO water systems is rife with potential. Emerging technologies, such as IoT-enabled monitoring and AI-driven maintenance solutions, promise to enhance system efficiency and predictive maintenance capabilities. These developments will cater to a demand for even more precise water quality management, where every drop counts. The ongoing research and investment in improving membrane materials and system design highlight the commitment of the industry to staying at the forefront of innovation. In conclusion, industrial RO water systems represent a critical intersection of capability, sustainability, and innovation. They serve as vital instruments not only in safeguarding water quality but also in driving operational success and environmental responsibility. Industrial leaders, stakeholders, and technical experts continue to cultivate these systems, ensuring their role as cornerstones in the quest for pure water, adapted to the dynamic landscape of modern industrial operations.

Expertise is a critical component in the deployment of industrial RO systems. Their installation and upkeep require skilled personnel well-versed in the intricacies of reverse osmosis technology. Proper training and certification ensure that technical teams can optimize system performance, troubleshoot issues promptly, and implement necessary upgrades effectively. A continuous emphasis on skill development is essential to maintaining optimal functionality and making informed adjustments as technological advancements occur. The authoritativeness of industrial RO systems lies in their widespread adoption and endorsement by leading industry bodies and regulatory agencies. Health authorities recognize these systems' ability to produce water of unparalleled purity—a standard necessary in sensitive applications such as medical device manufacturing and biotechnology. Industrial RO systems also align with regulatory compliance for wastewater disposal, providing peace of mind to facility operators concerned with legislation adherence. Trustworthiness in industrial RO systems is built upon a legacy of proven results and innovations tailored to evolving industry needs. Manufacturers of these systems foster trust through rigorous quality assurance protocols, transparent production practices, and consistent customer support. Industry leaders often share testimonials and case studies illustrating RO systems’ transformative impact on their operations, further solidifying their credibility. Looking forward, the future of industrial RO water systems is rife with potential. Emerging technologies, such as IoT-enabled monitoring and AI-driven maintenance solutions, promise to enhance system efficiency and predictive maintenance capabilities. These developments will cater to a demand for even more precise water quality management, where every drop counts. The ongoing research and investment in improving membrane materials and system design highlight the commitment of the industry to staying at the forefront of innovation. In conclusion, industrial RO water systems represent a critical intersection of capability, sustainability, and innovation. They serve as vital instruments not only in safeguarding water quality but also in driving operational success and environmental responsibility. Industrial leaders, stakeholders, and technical experts continue to cultivate these systems, ensuring their role as cornerstones in the quest for pure water, adapted to the dynamic landscape of modern industrial operations.

Share

Latest news

-

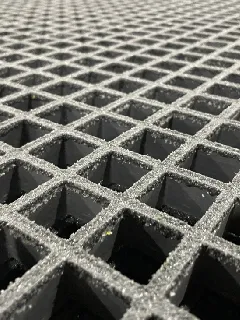

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024