loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 14, 2025 21:12

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

In industrial settings, the significance of maintaining clean and safe water cannot be overstated. Water is pivotal in countless processes, from cooling systems to manufacturing, and directly impacts both product quality and operational efficiency. The industrial water filter stands as a crucial component to ensure water integrity, making it an essential investment for any factory or plant aiming to meet both regulatory standards and production efficiency.

Innovations in the sector are continuously enhancing the expertise encapsulated in these systems. For instance, the integration of smart technology in modern industrial water filters enables real-time monitoring and management of filtration systems. By collecting data on water quality and filter performance, plants can optimize filter maintenance schedules, forecast potential issues, and ensure compliance with water usage standards, all contributing to a more efficient operation. Incorporating a robust industrial water filtration system isn't merely a matter of purchasing the right equipment; it also involves strategic planning and regular maintenance. Reliability hinges on selecting the appropriate system for specific industrial applications, considering factors such as water source, contaminant load, and required purity levels. Regular monitoring and maintenance further fortify trust and ensure long-term efficiency. Moreover, the synergy between industrial water filters and other plant processes is noteworthy. Advanced filtration systems not only safeguard water quality but also improve the effectiveness of chemical treatments and the efficiency of thermal systems. This holistic benefit underscores the filters' expertise in facilitating integrated plant operations, illustrating the far-reaching impact of clean water across diverse applications. The strategic value of industrial water filters extends beyond operational enhancements. By ensuring contaminant-free water, industries can mitigate risks associated with regulatory non-compliance and potential reputational damage. This aspect is especially vital in sectors where product quality directly influences brand perception, such as food and beverage or pharmaceuticals. In sum, the role of industrial water filters in today's manufacturing and production environments cannot be overemphasized. Their ability to deliver clean, compliant, and efficient water solutions renders them indispensable. From cost savings to regulatory compliance, these filters offer compelling advantages that resonate with industrial experts and authorities alike, reaffirming their position as cornerstones of modern industrial practices.

Innovations in the sector are continuously enhancing the expertise encapsulated in these systems. For instance, the integration of smart technology in modern industrial water filters enables real-time monitoring and management of filtration systems. By collecting data on water quality and filter performance, plants can optimize filter maintenance schedules, forecast potential issues, and ensure compliance with water usage standards, all contributing to a more efficient operation. Incorporating a robust industrial water filtration system isn't merely a matter of purchasing the right equipment; it also involves strategic planning and regular maintenance. Reliability hinges on selecting the appropriate system for specific industrial applications, considering factors such as water source, contaminant load, and required purity levels. Regular monitoring and maintenance further fortify trust and ensure long-term efficiency. Moreover, the synergy between industrial water filters and other plant processes is noteworthy. Advanced filtration systems not only safeguard water quality but also improve the effectiveness of chemical treatments and the efficiency of thermal systems. This holistic benefit underscores the filters' expertise in facilitating integrated plant operations, illustrating the far-reaching impact of clean water across diverse applications. The strategic value of industrial water filters extends beyond operational enhancements. By ensuring contaminant-free water, industries can mitigate risks associated with regulatory non-compliance and potential reputational damage. This aspect is especially vital in sectors where product quality directly influences brand perception, such as food and beverage or pharmaceuticals. In sum, the role of industrial water filters in today's manufacturing and production environments cannot be overemphasized. Their ability to deliver clean, compliant, and efficient water solutions renders them indispensable. From cost savings to regulatory compliance, these filters offer compelling advantages that resonate with industrial experts and authorities alike, reaffirming their position as cornerstones of modern industrial practices.

Share

Latest news

-

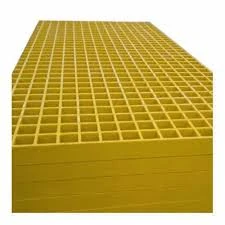

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024