loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 14, 2025 19:46

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

Industrial water treatment equipment is at the forefront of ensuring that industries do not only comply with environmental regulations but also optimize their operational efficiency. Cutting-edge technology and innovative designs in water treatment systems are addressing some of the most challenging environmental and operational problems industries face today. This article delves into the expertise, authoritative perspectives, and trustworthiness associated with advanced industrial water treatment equipment.

Advanced oxidation processes (AOP) are garnering attention for their ability to treat refractory organic compounds and sterilize water. AOP uses powerful oxidants such as ozone or hydrogen peroxide, often in conjunction with UV light, to break down contaminants. Industries dealing with complex wastewater scenarios rely on this technology for its proven track record in achieving compliance with discharge regulations. Noteworthy is the role of digital technology in enhancing the trustworthiness and efficiency of industrial water treatment systems. The integration of Internet of Things (IoT) and artificial intelligence (AI) into these systems allows for real-time monitoring, predictive maintenance, and enhanced operational insights. These advancements ensure that industrial processes run smoothly and errors are minimized, thereby saving time and resources. Experience in deploying and maintaining these complex systems is crucial. Consultation with industry veterans and credible suppliers can provide valuable insights and support during every stage of the water treatment process. From initial assessment to design and installation, to maintenance and optimization, experienced professionals bring an authoritative perspective that is indispensable for achieving the best outcomes. For businesses, selecting a reputable manufacturer and supplier is pivotal. It is advisable to verify that they hold industry certifications and can provide case studies demonstrating the effectiveness of their solutions across various industry scenarios. Trustworthy suppliers are transparent about their processes and are committed to continuous improvement and customer satisfaction. In conclusion, industrial water treatment equipment represents a blend of cutting-edge technology, expert knowledge, and industry authority. These systems are pivotal not only for regulatory compliance and environmental stewardship but also for enhancing operational efficiency. The future of industrial water treatment is bright, with ongoing innovations promising even greater advances in capability and performance. Careful selection and implementation of these systems, supported by credible expertise and authoritative insight, are crucial in meeting today’s industrial challenges head-on.

Advanced oxidation processes (AOP) are garnering attention for their ability to treat refractory organic compounds and sterilize water. AOP uses powerful oxidants such as ozone or hydrogen peroxide, often in conjunction with UV light, to break down contaminants. Industries dealing with complex wastewater scenarios rely on this technology for its proven track record in achieving compliance with discharge regulations. Noteworthy is the role of digital technology in enhancing the trustworthiness and efficiency of industrial water treatment systems. The integration of Internet of Things (IoT) and artificial intelligence (AI) into these systems allows for real-time monitoring, predictive maintenance, and enhanced operational insights. These advancements ensure that industrial processes run smoothly and errors are minimized, thereby saving time and resources. Experience in deploying and maintaining these complex systems is crucial. Consultation with industry veterans and credible suppliers can provide valuable insights and support during every stage of the water treatment process. From initial assessment to design and installation, to maintenance and optimization, experienced professionals bring an authoritative perspective that is indispensable for achieving the best outcomes. For businesses, selecting a reputable manufacturer and supplier is pivotal. It is advisable to verify that they hold industry certifications and can provide case studies demonstrating the effectiveness of their solutions across various industry scenarios. Trustworthy suppliers are transparent about their processes and are committed to continuous improvement and customer satisfaction. In conclusion, industrial water treatment equipment represents a blend of cutting-edge technology, expert knowledge, and industry authority. These systems are pivotal not only for regulatory compliance and environmental stewardship but also for enhancing operational efficiency. The future of industrial water treatment is bright, with ongoing innovations promising even greater advances in capability and performance. Careful selection and implementation of these systems, supported by credible expertise and authoritative insight, are crucial in meeting today’s industrial challenges head-on.

Share

Latest news

-

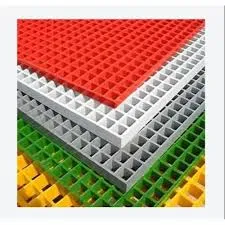

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024