loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Understanding the Functionality of Media Filter Vessels in Water Treatment Systems

Understanding Media Filter Vessels An Essential Component in Water Treatment

Media filter vessels play a pivotal role in the field of water treatment, serving as crucial components in various filtration processes. These specialized tanks are designed to remove suspended solids, turbidity, and other impurities from water, ensuring that it meets safety and quality standards for consumption and industrial use. This article delves into the construction, operation, and applications of media filter vessels, highlighting their importance in modern water treatment systems.

Construction and Design

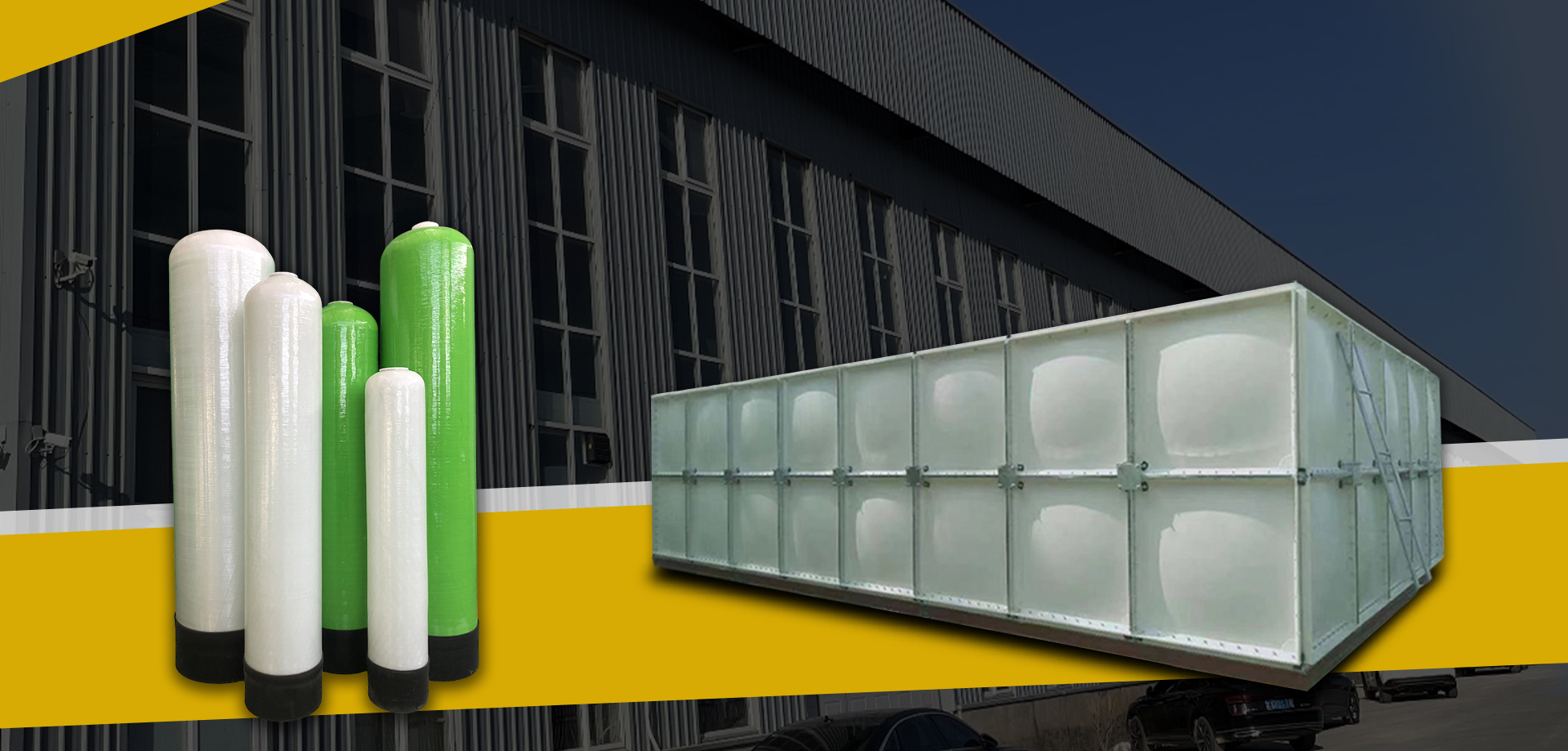

Media filter vessels are typically cylindrical tanks made from materials such as steel, fiberglass, or reinforced plastics. The design of these vessels allows for the efficient distribution and flow of water through the filtering media. Inside the vessel, a layer of filtration media is placed, which can include various materials such as sand, gravel, activated carbon, or specially designed synthetic media. The choice of media depends on the specific contaminants to be removed and the characteristics of the water being treated.

The vessel is equipped with inlet and outlet pipes, as well as a system for backwashing, which is essential for maintaining filter performance. Backwashing involves reversing the flow of water to dislodge trapped particles and contaminants, thereby renewing the media's effectiveness. Regular maintenance and monitoring are critical to ensure that the media filter vessel operates optimally.

Operation Principles

The operation of a media filter vessel is relatively straightforward but relies on fundamental principles of physics. When water enters the vessel, it is directed through the filtration media. As the water flows downwards (in gravity-fed systems) or upwards (in pressure systems), the media captures and holds back suspended solids and larger particles based on size exclusion. Additionally, certain media, such as activated carbon, can adsorb dissolved contaminants, further purifying the water.

media filter vessel

The efficiency of a media filter vessel can be affected by various factors, including the flow rate, the type and size of the filtration media, and the presence of any pretreatment systems. For instance, pre-filtering water to remove larger debris can enhance the lifespan of the media and improve overall performance.

Applications Across Industries

Media filter vessels are widely employed in various sectors, including municipal water treatment, industrial processes, aquaculture, and wastewater management. In municipal settings, they are essential in producing safe drinking water, removing turbidity and pathogenic microorganisms effectively. In industrial applications, these vessels are used to treat process water, cooling tower water, and effluents, ensuring compliance with environmental regulations.

In aquaculture, media filters help maintain water quality in fish farms, removing excess nutrients and organic matter that could harm aquatic life. Similarly, wastewater treatment facilities utilize media filters to clarify effluent before it is discharged or further treated.

Conclusion

In summary, media filter vessels are indispensable in ensuring the purity and safety of water in various applications. Their effective design, coupled with the versatility of different filtration media, makes them suitable for a wide range of contexts. As global water scarcity continues to be a pressing issue, the importance of efficient filtration systems like media filter vessels will only grow. Investing in advanced filtration technologies and maintaining existing systems will be crucial for safeguarding our water resources and meeting the increasing demand for clean water worldwide.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024