loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 14, 2025 15:48

Back to list

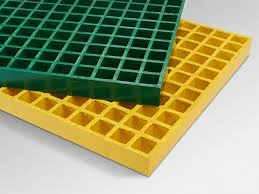

frp grating

In recent years, the demand for membrane housing has dramatically risen across various industries due to their pivotal role in water purification, filtration systems, and other critical applications. Membrane housings play an integral part in ensuring the longevity and efficiency of filtration membranes, which are crucial for clean water access, among other uses. This article delves into the significance of membrane housing, underlining its construction, expert recommendations, and industry standards that enhance its credibility and trustworthiness for potential buyers.

In addition to design considerations, the maintenance and installation of membrane housings are crucial for sustained performance and reliability. Experienced technicians emphasize regular inspections and cleaning procedures to prevent fouling and scaling, which can impede the functionality of both the housing and the membranes themselves. By using non-abrasive cleaning agents and ensuring that seals and gaskets are intact and free of wear, operators can extend the life of their membrane systems significantly. Proper training in these maintenance protocols is essential, as it empowers facility managers and technicians to make informed decisions, thus protecting the operational integrity of their equipment. Transparency in sourcing and manufacturing processes boosts trustworthiness. Leading manufacturers provide detailed documentation on the origin of materials, compliance with international standards, and the environmental considerations of their products. In an era where sustainability is increasingly prioritized, companies that showcase their commitment to environmentally-friendly practices are often viewed more favorably. This encompasses not only the production of the membrane housings themselves but extends to their lifecycle management, including recycling opportunities at the end of their operational life. The authoritative nature of well-crafted membrane housings is also a reflection of technological advancements in the field. Cutting-edge designs now incorporate smart technologies, allowing for real-time monitoring of system status, pressure levels, and potential malfunctions. These intelligent systems enable proactive maintenance and immediate troubleshooting, reducing downtime and associated costs. Industry leaders who integrate such innovations demonstrate their expertise, creating competitive advantages and reinforcing their reputations as pioneers in the field. In conclusion, membrane housing remains a cornerstone in the effectiveness of filtration systems across diverse industries. With a strong foundation in material science, precise engineering, and consistent quality control, these components not only meet but often exceed industry standards. By embracing customization, diligent maintenance, transparent practices, and innovative technologies, manufacturers and end-users alike can reinforce the expertise and trust vested in membrane housings as vital assets in achieving operational excellence.

In addition to design considerations, the maintenance and installation of membrane housings are crucial for sustained performance and reliability. Experienced technicians emphasize regular inspections and cleaning procedures to prevent fouling and scaling, which can impede the functionality of both the housing and the membranes themselves. By using non-abrasive cleaning agents and ensuring that seals and gaskets are intact and free of wear, operators can extend the life of their membrane systems significantly. Proper training in these maintenance protocols is essential, as it empowers facility managers and technicians to make informed decisions, thus protecting the operational integrity of their equipment. Transparency in sourcing and manufacturing processes boosts trustworthiness. Leading manufacturers provide detailed documentation on the origin of materials, compliance with international standards, and the environmental considerations of their products. In an era where sustainability is increasingly prioritized, companies that showcase their commitment to environmentally-friendly practices are often viewed more favorably. This encompasses not only the production of the membrane housings themselves but extends to their lifecycle management, including recycling opportunities at the end of their operational life. The authoritative nature of well-crafted membrane housings is also a reflection of technological advancements in the field. Cutting-edge designs now incorporate smart technologies, allowing for real-time monitoring of system status, pressure levels, and potential malfunctions. These intelligent systems enable proactive maintenance and immediate troubleshooting, reducing downtime and associated costs. Industry leaders who integrate such innovations demonstrate their expertise, creating competitive advantages and reinforcing their reputations as pioneers in the field. In conclusion, membrane housing remains a cornerstone in the effectiveness of filtration systems across diverse industries. With a strong foundation in material science, precise engineering, and consistent quality control, these components not only meet but often exceed industry standards. By embracing customization, diligent maintenance, transparent practices, and innovative technologies, manufacturers and end-users alike can reinforce the expertise and trust vested in membrane housings as vital assets in achieving operational excellence.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024