loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

metal bar grating

Understanding Metal Bar Grating A Comprehensive Overview

Metal bar grating is an essential component in various industrial and commercial applications, providing both functionality and structural integrity. This versatile material is created by forging or welding metal bars into a grid-like pattern, resulting in a product that combines strength, durability, and safety. It is widely used in environments that require heavy-duty flooring, walkways, drainage covers, and more.

Composition and Types of Metal Bar Grating

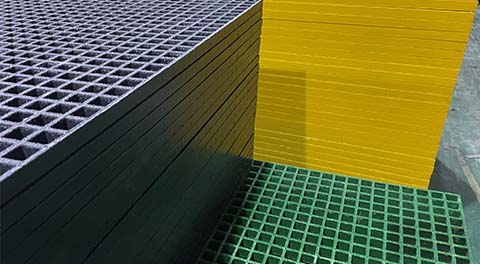

Metal bar grating is predominantly made from materials such as steel, stainless steel, aluminum, or fiberglass. Each material has its specific properties, making them suitable for different applications. For instance, steel grating is known for its strength and cost-effectiveness, while aluminum grating is lightweight and resistant to corrosion, making it ideal for outdoor applications.

There are several types of metal bar grating, including

1. Type of Layout Gratings can be configured in different layouts, such as welded, pressure-locked, and riveted. Welded gratings are the most common, providing exceptional strength and stability. Pressure-locked grating employs a locking mechanism to hold the bars in place, making it suitable for heavy loads.

2. Bar Spacing The spacing between the bars can vary, affecting load capacity and the type of materials that can pass through the grating. Closer spacing is often utilized in areas where small items or debris could fall through.

3. Surface Finish The surface of metal grating can be treated or coated with various finishes to enhance its resistance to rust and wear. Options include hot-dip galvanizing, powder coating, and anodizing, each providing varying levels of protection depending on the environment.

Applications of Metal Bar Grating

Metal bar grating finds applications across a range of industries, including

- Industrial Flooring Used in warehouses and factories, metal gratings provide a sturdy walking surface that allows for the swift movement of machinery and personnel while facilitating the drainage of liquids.

metal bar grating

- Platforms and Walkways Grating is an excellent choice for outdoor walkways, as it minimizes snow and ice build-up while providing a slip-resistant surface.

- Covers and Trench Drains In construction and civil engineering, metal grating is often used for trench covers, offering safety and efficiency in stormwater management systems.

- Electrical Applications Metal gratings are used in electrical substations and power plants for safe access to equipment while allowing for ventilation.

Benefits of Metal Bar Grating

The benefits of metal bar grating are numerous

- Durability With high tensile strength, metal grating can withstand heavy loads and harsh environmental conditions, ensuring a long lifespan.

- Cost-Effective Due to its robustness and low maintenance requirements, metal gratings present a cost-effective solution for many applications.

- Safety The open design of metal gratings provides excellent drainage, reduces slip hazards, and allows for visibility of underlying areas.

- Customization Manufacturers can customize metal bar grating according to specific requirements, including size, weight capacity, and surface treatment.

Conclusion

In summary, metal bar grating is a fundamental element in various sectors, offering an efficient and reliable solution for numerous applications. Its strength, versatility, and safety features make it a popular choice for many industries, ensuring that operational needs are met while promoting workplace safety and efficiency. As industries continue to evolve, metal bar grating will remain an integral part of modern infrastructure.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024