loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 11, 2025 09:45

Back to list

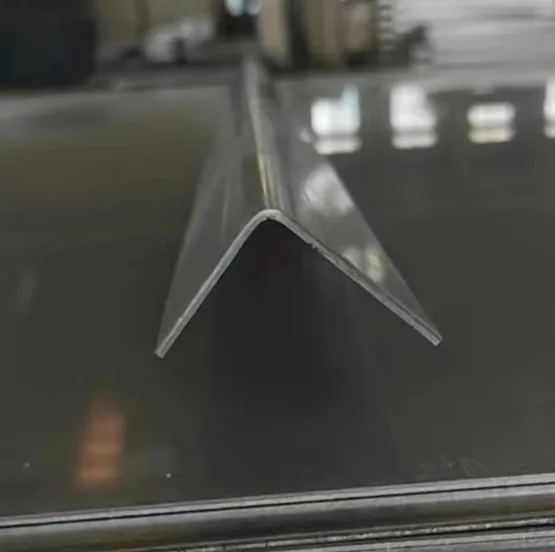

micro mesh grating

Micro mesh grating is revolutionizing industries that rely on strong, durable, and versatile materials. A closer examination reveals why companies across various sectors are making the switch to this innovative material, enhancing their operations through improved safety, efficiency, and practicality.

Moreover, the expertise behind designing micro mesh grating ensures that it meets or exceeds industry standards for performance and safety. Manufacturing leaders in the field employ stringent quality controls and testing methodologies, ensuring that each piece of grating can withstand extreme load bearings and harsh environmental factors. Companies need materials they can trust, and rightly so. With micro mesh grating, they gain a dependable ally in their infrastructure that assures continuity and reliability, even under intense conditions. The authority of micro mesh grating in the market continues to grow, supported by an increasing number of testimonials from industry professionals who express satisfaction with its performance. An expert in commercial flooring systems quoted that after switching to micro mesh grating, not only did the maintenance frequency of floor installations drop dramatically, but the feedback from staff regarding enhanced safety and convenience was overwhelmingly positive. Such experiences fuel the narrative of micro mesh grating's indispensability for industrial safety enhancements. For companies analyzing the investment potential in micro mesh grating, the trust in this product stems from its proven track record. It is a decision attuned to long-term benefits in safety, cost-effectiveness, and durability. Research indicates that facilities using micro mesh grating report fewer safety incidents, pointing to a direct correlation between this advanced material and improved operational safety metrics. In summary, micro mesh grating isn't just a product; it's a strategic asset for businesses focused on optimizing their operations and safety protocols. Its unique combination of strength, reliability, and practicality makes it an essential material in today's industrial infrastructure landscape. Trust in its deployment is echoed by industry leaders who have seen firsthand transformations in their operational efficacy, reflecting micro mesh grating's unmatched value across various applications.

Moreover, the expertise behind designing micro mesh grating ensures that it meets or exceeds industry standards for performance and safety. Manufacturing leaders in the field employ stringent quality controls and testing methodologies, ensuring that each piece of grating can withstand extreme load bearings and harsh environmental factors. Companies need materials they can trust, and rightly so. With micro mesh grating, they gain a dependable ally in their infrastructure that assures continuity and reliability, even under intense conditions. The authority of micro mesh grating in the market continues to grow, supported by an increasing number of testimonials from industry professionals who express satisfaction with its performance. An expert in commercial flooring systems quoted that after switching to micro mesh grating, not only did the maintenance frequency of floor installations drop dramatically, but the feedback from staff regarding enhanced safety and convenience was overwhelmingly positive. Such experiences fuel the narrative of micro mesh grating's indispensability for industrial safety enhancements. For companies analyzing the investment potential in micro mesh grating, the trust in this product stems from its proven track record. It is a decision attuned to long-term benefits in safety, cost-effectiveness, and durability. Research indicates that facilities using micro mesh grating report fewer safety incidents, pointing to a direct correlation between this advanced material and improved operational safety metrics. In summary, micro mesh grating isn't just a product; it's a strategic asset for businesses focused on optimizing their operations and safety protocols. Its unique combination of strength, reliability, and practicality makes it an essential material in today's industrial infrastructure landscape. Trust in its deployment is echoed by industry leaders who have seen firsthand transformations in their operational efficacy, reflecting micro mesh grating's unmatched value across various applications.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024