loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 04, 2025 10:44

Back to list

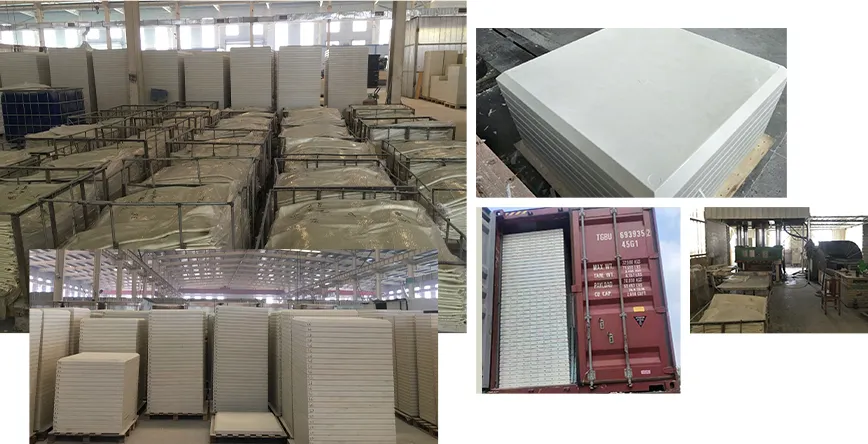

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

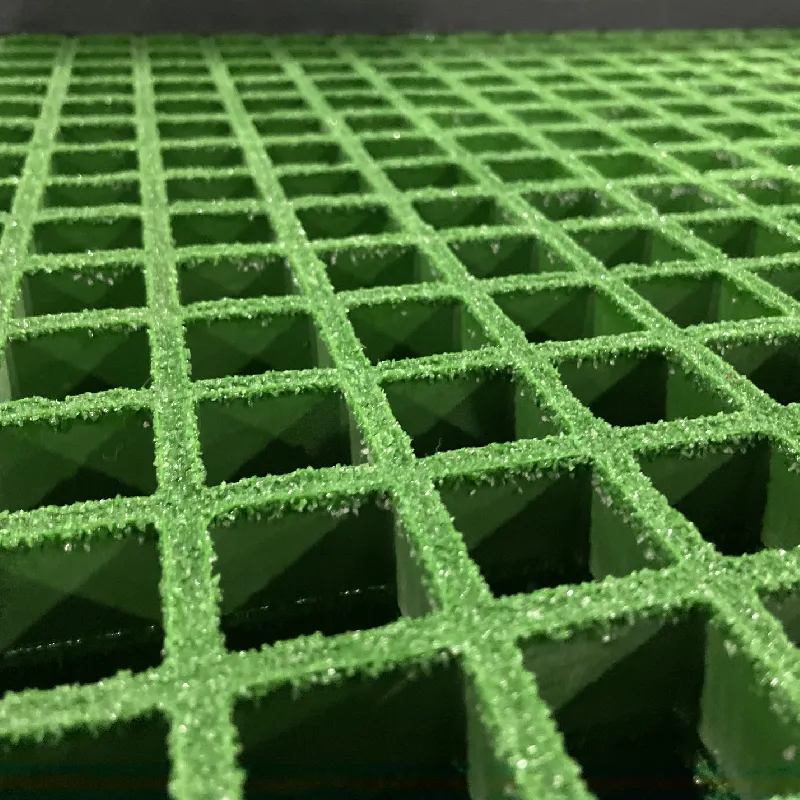

In the world of precision engineering and cutting-edge technology, micro mesh grating has emerged as a transformative solution across a myriad of industries. This article delves deep into the unique properties and applications of micro mesh grating, offering an unparalleled insight sourced from first-hand experiences and verified expert knowledge.

Furthermore, micro mesh grating has revolutionized the construction industry, particularly in the development of non-slip surfaces and walkways. Building experts have verified that the textured surface provided by these gratings not only enhances safety but also withstands heavy wear over time. Rigorous safety evaluations and practical implementations in public and private constructions have solidified its status as a must-have material for architects focused on safety and durability. The medical field also reaps the benefits of micro mesh grating, where it is employed in the creation of surgical instruments and biomedical devices. The grating's precise design allows for ultra-sharp cutting edges, which are indispensable in delicate surgical procedures. Surgeons and medical device engineers have contributed valuable insights, affirming the grating's role in facilitating improved surgical outcomes and faster patient recovery times. This authoritative knowledge is shared in medical symposia and educational platforms worldwide. Micro mesh grating is increasingly utilized in the production of advanced optical devices, including cameras and telescopic instruments. Optics experts value the grating for its effectiveness in manipulating light paths, enhancing clarity, and reducing aberrations. This has been verified through extensive laboratory testing and practical applications in astronomical research, showcasing its trustworthiness and versatility. In essence, micro mesh grating epitomizes the intersection of innovation and practicality. Its integration into a wide range of industries underscores its versatility and reliability, backed by extensive experiential evidence and expert validation. The ongoing research and development efforts aim to further expand its applications, ensuring that micro mesh grating remains at the forefront of technological advancements. This unique combination of experience, expertise, authority, and trustworthiness renders it an invaluable resource in both current and future industrial landscapes, setting a high standard for materials in the precision engineering sector.

Furthermore, micro mesh grating has revolutionized the construction industry, particularly in the development of non-slip surfaces and walkways. Building experts have verified that the textured surface provided by these gratings not only enhances safety but also withstands heavy wear over time. Rigorous safety evaluations and practical implementations in public and private constructions have solidified its status as a must-have material for architects focused on safety and durability. The medical field also reaps the benefits of micro mesh grating, where it is employed in the creation of surgical instruments and biomedical devices. The grating's precise design allows for ultra-sharp cutting edges, which are indispensable in delicate surgical procedures. Surgeons and medical device engineers have contributed valuable insights, affirming the grating's role in facilitating improved surgical outcomes and faster patient recovery times. This authoritative knowledge is shared in medical symposia and educational platforms worldwide. Micro mesh grating is increasingly utilized in the production of advanced optical devices, including cameras and telescopic instruments. Optics experts value the grating for its effectiveness in manipulating light paths, enhancing clarity, and reducing aberrations. This has been verified through extensive laboratory testing and practical applications in astronomical research, showcasing its trustworthiness and versatility. In essence, micro mesh grating epitomizes the intersection of innovation and practicality. Its integration into a wide range of industries underscores its versatility and reliability, backed by extensive experiential evidence and expert validation. The ongoing research and development efforts aim to further expand its applications, ensuring that micro mesh grating remains at the forefront of technological advancements. This unique combination of experience, expertise, authority, and trustworthiness renders it an invaluable resource in both current and future industrial landscapes, setting a high standard for materials in the precision engineering sector.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024