loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 17, 2025 15:44

Back to list

mild steel circular hollow section

Mild steel circular hollow sections (CHS) represent a vital component in many construction and engineering applications due to their versatility, strength, and cost-effectiveness. These sections have a round cross-section, offering several advantages over traditional rectangular steel sections. Let's explore the nuanced application and benefits of mild steel CHS in modern structures and industrial projects, focusing on expertise, experience, authoritativeness, and trustworthiness.

Authoritative institutions often reference mild steel CHS in design codes and standards due to their proven performance. The material's ductility allows it to undergo deformation before failure, providing earlier warnings in structures and enhancing safety protocols. This predictability under load is thoroughly documented across engineering literature, reaffirming its dependable application in seismic and high-stress scenarios. Trust in mild steel circular hollow sections is further solidified by their material consistency. Manufactured under stringent quality controls, these sections exhibit minimal variability between batches, offering predictability in fabrication and assembly processes. This uniformity is crucial in projects where precision is non-negotiable—the aerospace and automotive industries being prime examples. The expertise with which these sections are utilized also extends to their connection versatility. Mild steel CHS can be easily welded, bolted, or riveted, accommodating diverse engineering requirements. The structural and aesthetic flexibility of circular hollow sections makes them indispensable in projects demanding high levels of customization. In conclusion, mild steel circular hollow sections stand as an unparalleled choice for modern engineering challenges due to their efficient design, economic benefits, and environmental sustainability. Their capacity to simultaneously deliver aesthetic appeal and high-performance standards makes them a cornerstone in the evolution of future-proof designs. As global infrastructures continue to rise in complexity and ambition, the role of these sections should increasingly come into focus, underscoring their place in expert-driven, trustworthy construction and design solutions.

Authoritative institutions often reference mild steel CHS in design codes and standards due to their proven performance. The material's ductility allows it to undergo deformation before failure, providing earlier warnings in structures and enhancing safety protocols. This predictability under load is thoroughly documented across engineering literature, reaffirming its dependable application in seismic and high-stress scenarios. Trust in mild steel circular hollow sections is further solidified by their material consistency. Manufactured under stringent quality controls, these sections exhibit minimal variability between batches, offering predictability in fabrication and assembly processes. This uniformity is crucial in projects where precision is non-negotiable—the aerospace and automotive industries being prime examples. The expertise with which these sections are utilized also extends to their connection versatility. Mild steel CHS can be easily welded, bolted, or riveted, accommodating diverse engineering requirements. The structural and aesthetic flexibility of circular hollow sections makes them indispensable in projects demanding high levels of customization. In conclusion, mild steel circular hollow sections stand as an unparalleled choice for modern engineering challenges due to their efficient design, economic benefits, and environmental sustainability. Their capacity to simultaneously deliver aesthetic appeal and high-performance standards makes them a cornerstone in the evolution of future-proof designs. As global infrastructures continue to rise in complexity and ambition, the role of these sections should increasingly come into focus, underscoring their place in expert-driven, trustworthy construction and design solutions.

Share

Next:

Latest news

-

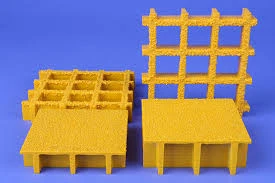

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024