loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advantages of Molded Fiberglass Grating in Industrial Applications and Construction

The Advantages of Molded Fiberglass Grating

Molded fiberglass grating has become an increasingly popular choice in various industries due to its numerous advantages over traditional grating materials such as steel, aluminum, or wood. This innovative material combines durability, strength, and a range of other beneficial properties, making it suitable for various applications, from industrial to commercial settings.

Versatility and Design Flexibility

One of the primary advantages of molded fiberglass grating is its versatility. Available in various sizes, shapes, and colors, it can be customized to meet specific design requirements. This flexibility allows architects and engineers to create aesthetically pleasing environments without compromising on safety or functionality. Fiberglass grating can be manufactured to meet specific load-bearing requirements, making it an ideal solution for various applications, including walkways, platforms, and stair treads.

Strength and Durability

Molded fiberglass grating is renowned for its exceptional strength-to-weight ratio. It has the ability to withstand high loads, making it suitable for heavy-duty applications. Unlike traditional materials, fiberglass does not corrode or degrade when exposed to harsh chemicals, moisture, or extreme temperatures. This characteristic makes it an ideal choice for industries such as chemical processing, wastewater treatment, and food processing, where exposure to corrosive substances is common.

Lightweight and Easy to Install

Another significant advantage of molded fiberglass grating is its lightweight nature. This feature makes it easier and more cost-effective to transport and install compared to heavier materials like steel. Reduced labor costs and simplified installation processes lead to significant savings for construction projects. Additionally, the lightweight design of fiberglass grating reduces the overall load on supporting structures, ensuring enhanced stability and safety.

Safety Features

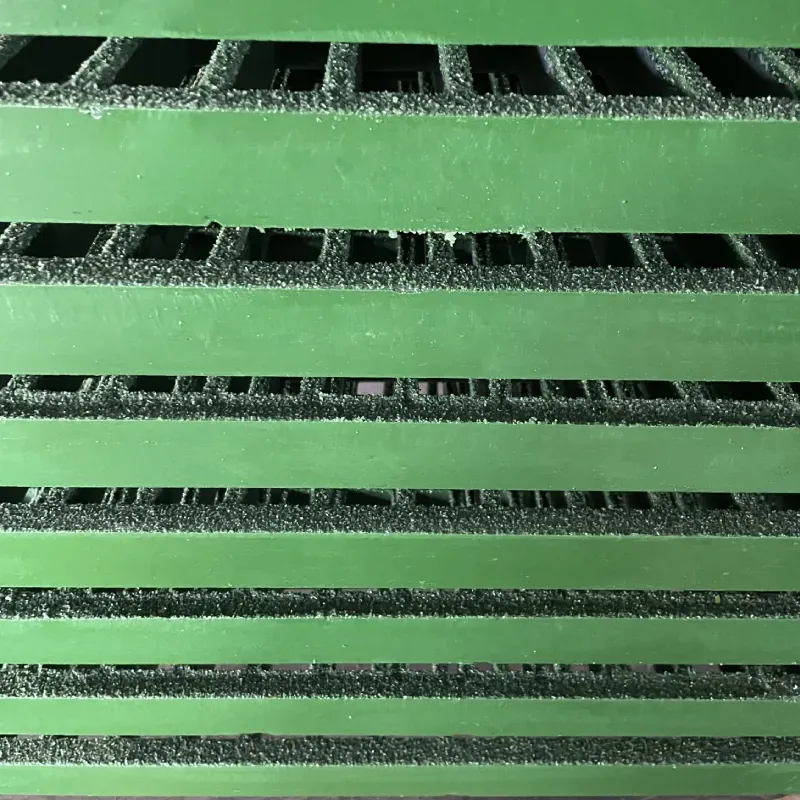

molded fiberglass grating

Safety is a paramount concern in any industrial setting, and molded fiberglass grating excels in this area as well. Many manufacturers incorporate slip-resistant surfaces, which significantly reduce the risk of slips and falls, making it safer for workers navigating wet or oily environments. The grating is also available in various colors, allowing for better visibility in low-light conditions. Furthermore, fiberglass does not conduct electricity, adding an extra layer of safety in electrical-related applications.

Low Maintenance

Molded fiberglass grating is virtually maintenance-free, reducing long-term operational costs. Unlike steel, it does not require regular painting or rust prevention treatments. Cleaning is straightforward a simple wash with water and mild detergent usually suffices. This low maintenance requirement results in fewer disruptions to operations and greater productivity overall.

Environmental Considerations

In today’s environmentally-conscious world, molded fiberglass grating has a distinct edge due to its sustainable qualities. Many manufacturers focus on using recycled materials in the production process. Additionally, the long service life of fiberglass reduces the need for frequent replacements, leading to less waste. As industries strive to minimize their environmental footprint, choosing fiberglass grating aligns with these goals.

Cost-Effectiveness

While the initial investment in molded fiberglass grating might be higher than traditional materials, the long-term savings in maintenance, replacement, and installation costs make it a cost-effective solution. Its durability and resistance to wear and tear mean organizations can expect a much longer service life with minimal expenses over time.

Conclusion

Molded fiberglass grating represents a modern solution that embraces both functionality and safety, catering to the needs of various industries. Its combination of strength, lightweight construction, low maintenance, and environmental sustainability makes it an appealing choice for architects, engineers, and project managers. As industries continue to evolve and seek out innovative materials, molded fiberglass grating will undoubtedly play a crucial role in shaping safer and more efficient working environments.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024