loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 20, 2025 13:33

Back to list

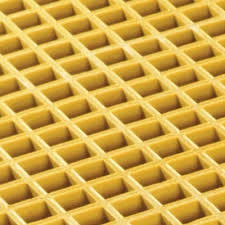

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Molded fiberglass grating has emerged as a revolutionary material, highly regarded for its versatile applications across multiple industries. Known for combining strength, durability, and excellent corrosion resistance, molded fiberglass grating offers significant advantages over traditional materials like steel or wood. Below is an in-depth evaluation of molded fiberglass grating to help professionals and enthusiasts understand the unparalleled benefits of integrating this material into their projects.

In terms of trustworthiness, molded fiberglass grating comes backed by exhaustive warranties and certifications from leading manufacturers globally, underscoring their reliability. Sustainability is yet another critical aspect, as these grates are environmentally friendly; they emit no toxic substances and boast a long lifecycle. Consequently, businesses seeking to reduce their ecological footprint can rely on molded fiberglass grating as a viable alternative. Drawing from real-world applications, one notable case involved a coastal municipality replacing their old, corroded steel walkways with molded fiberglass grating. Post-installation, maintenance costs were drastically reduced, and the grating's solid slip-resistant surface enhanced public safety along the waterfront, demonstrating both the economic and practical advantages of this material. Professionals dedicated to staying ahead in their fields appreciate the long-term benefits offered by molded fiberglass grating. By effectively reducing lifecycle costs thanks to its durability and minimal upkeep, businesses can allocate resources more effectively, ensuring operational efficiency and safety. Furthermore, as industries continue to push towards more sustainable practices, molded fiberglass grating stands out for its low environmental impact and recyclability. In summary, molded fiberglass grating offers a sophisticated solution tailored to meet the complex demands of modern infrastructures. Its exceptional properties, validated by extensive real-world applications and compliance with international standards, position it as a leading material choice. From economic to environmental benefits, it promises to revolutionize how industries approach construction, safety, and efficiency, making molded fiberglass grating a wise investment for the future.

In terms of trustworthiness, molded fiberglass grating comes backed by exhaustive warranties and certifications from leading manufacturers globally, underscoring their reliability. Sustainability is yet another critical aspect, as these grates are environmentally friendly; they emit no toxic substances and boast a long lifecycle. Consequently, businesses seeking to reduce their ecological footprint can rely on molded fiberglass grating as a viable alternative. Drawing from real-world applications, one notable case involved a coastal municipality replacing their old, corroded steel walkways with molded fiberglass grating. Post-installation, maintenance costs were drastically reduced, and the grating's solid slip-resistant surface enhanced public safety along the waterfront, demonstrating both the economic and practical advantages of this material. Professionals dedicated to staying ahead in their fields appreciate the long-term benefits offered by molded fiberglass grating. By effectively reducing lifecycle costs thanks to its durability and minimal upkeep, businesses can allocate resources more effectively, ensuring operational efficiency and safety. Furthermore, as industries continue to push towards more sustainable practices, molded fiberglass grating stands out for its low environmental impact and recyclability. In summary, molded fiberglass grating offers a sophisticated solution tailored to meet the complex demands of modern infrastructures. Its exceptional properties, validated by extensive real-world applications and compliance with international standards, position it as a leading material choice. From economic to environmental benefits, it promises to revolutionize how industries approach construction, safety, and efficiency, making molded fiberglass grating a wise investment for the future.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024