loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

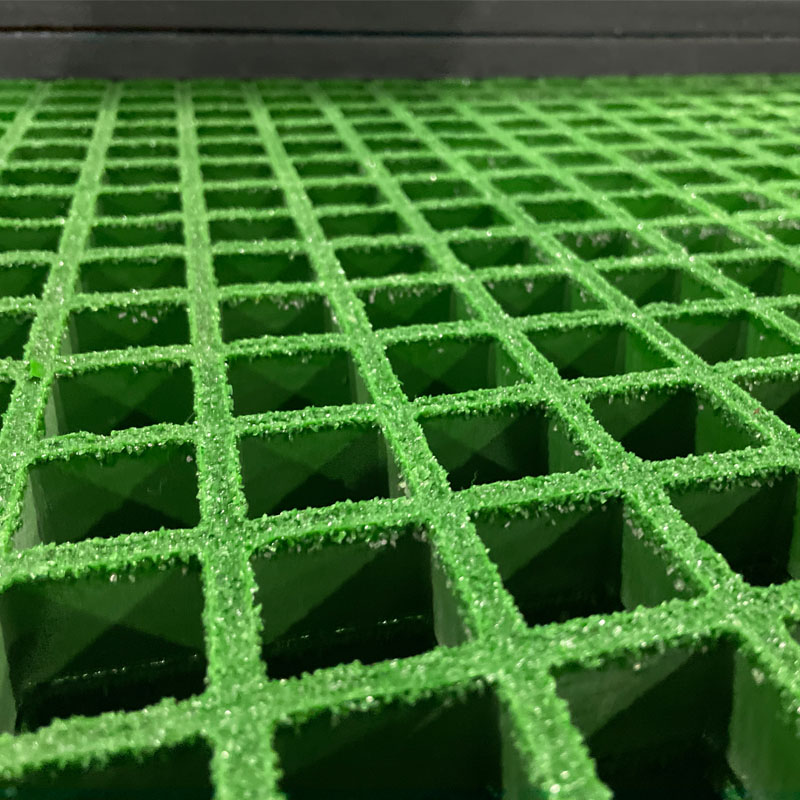

molded grating

Molded Grating An Innovative Solution for Various Applications

Molded grating is a versatile and innovative product widely used across various industries due to its numerous advantages. Composed of fiberglass reinforced plastic (FRP), molded grating offers a robust alternative to traditional materials like wood and metal. Its unique manufacturing process and properties make it an excellent choice for applications requiring durability, corrosion resistance, and low maintenance.

A key advantage of molded grating is its lightweight nature, making it easier to handle and install compared to heavier materials. This attribute significantly reduces labor costs and time during installation, which can be a crucial factor in project timelines. The ease of installation also brings about increased safety on site, as fewer resources are needed to lift and position the grating.

Corrosion resistance is another significant benefit of molded grating

. In environments where exposure to chemicals, moisture, or salt is prevalent, conventional metals such as steel can corrode, leading to safety hazards and increased maintenance costs. Molded grating, on the other hand, remains unaffected by these conditions, making it an ideal choice for industries such as wastewater treatment, chemical processing, and food and beverage manufacturing.molded grating

Furthermore, molded grating is designed with slip-resistant surfaces that enhance safety in workplaces where spills or wet conditions might be common. This feature ensures that employees can move safely across walkways and platforms, reducing the likelihood of accidents and injuries. Additionally, many molded grating products are available in various colors and patterns, enabling customization to fit aesthetic needs while providing functional benefits.

The versatility of molded grating extends across various applications. It can be used for walkways, platforms, stair treads, and even drainage covers, serving industries from construction to aerospace. Its light weight contributes significantly to the ease of transportation and deployment, which is advantageous in dynamic environments such as construction sites and manufacturing plants.

Molded grating also has an impressive lifespan. Compared to traditional materials, FRP grating does not warp, rot, or rust, contributing to long-term cost savings. The reduced need for replacement leads to less waste, aligning with sustainability practices that many industries are now adopting. Additionally, its resistance to UV radiation ensures that the aesthetics and functionality of the grating remain intact over time.

In conclusion, molded grating stands out as a cutting-edge solution tailored to meet the demands of modern industries. Its lightweight composition, exceptional corrosion resistance, slip-resistant properties, and versatility make it a preferred choice for engineers and designers. As industries continue to prioritize safety, efficiency, and sustainability, molded grating is poised to play an increasingly significant role in various applications. Whether in harsh industrial environments or everyday facilities, molded grating provides a reliable, durable platform that meets the challenges of today’s infrastructure needs.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024