loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 20, 2025 14:45

Back to list

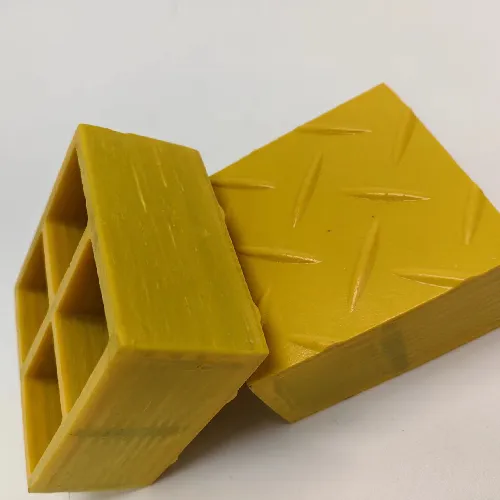

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Moulded grating, often a staple in industrial and commercial environments, offers an array of benefits that outperform traditional materials such as wood, steel, and aluminium. This thermoset resin composite is recognized for its durability, non-corrosive properties, and impressive load-bearing capabilities, making it an ideal choice for a variety of applications.

The environmental benefits of moulded grating add yet another layer to its appeal. With a growing emphasis on sustainable practices, industries are recognizing the importance of materials that not only perform well but also contribute to eco-friendly goals. Moulded grating's long lifespan and minimal maintenance requirements mean less frequent replacements and reduced environmental impact — contributing to lower carbon footprints. Furthermore, the customization possibilities with moulded grating are virtually endless. It can be fabricated in a range of sizes, shapes, and colors to meet specific requirements, enhancing both the functionality and aesthetic appeal of the workspace. This level of customization ensures that the grating integrates seamlessly with existing designs, fulfilling both practical and design-oriented needs. Professionals looking to source the best moulded grating must consider suppliers with proven expertise in composite materials. A reputable supplier will offer a product that meets stringent quality standards, backed by an extensive track record of successful installations. Opt for manufacturers who can provide certifications and warranties to ensure authenticity and peace of mind. Ultimately, integrating moulded grating into your facility is a strategic move that promises longevity, versatility, and safety, aligning perfectly with modern industrial demands. Its multifaceted benefits underscore why it is not just a viable option, but often the preferred choice among engineers and safety officers alike. When you choose moulded grating, you invest not just in a product, but in a long-term solution that enhances operational efficiency and safety, positioning your business at the forefront of industry best practices.

The environmental benefits of moulded grating add yet another layer to its appeal. With a growing emphasis on sustainable practices, industries are recognizing the importance of materials that not only perform well but also contribute to eco-friendly goals. Moulded grating's long lifespan and minimal maintenance requirements mean less frequent replacements and reduced environmental impact — contributing to lower carbon footprints. Furthermore, the customization possibilities with moulded grating are virtually endless. It can be fabricated in a range of sizes, shapes, and colors to meet specific requirements, enhancing both the functionality and aesthetic appeal of the workspace. This level of customization ensures that the grating integrates seamlessly with existing designs, fulfilling both practical and design-oriented needs. Professionals looking to source the best moulded grating must consider suppliers with proven expertise in composite materials. A reputable supplier will offer a product that meets stringent quality standards, backed by an extensive track record of successful installations. Opt for manufacturers who can provide certifications and warranties to ensure authenticity and peace of mind. Ultimately, integrating moulded grating into your facility is a strategic move that promises longevity, versatility, and safety, aligning perfectly with modern industrial demands. Its multifaceted benefits underscore why it is not just a viable option, but often the preferred choice among engineers and safety officers alike. When you choose moulded grating, you invest not just in a product, but in a long-term solution that enhances operational efficiency and safety, positioning your business at the forefront of industry best practices.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024