loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 12, 2025 23:06

Back to list

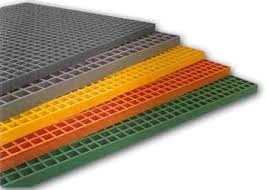

frp pultruded gratings

Moulded gratings have emerged as an essential component in various industrial applications, offering key benefits that make them indispensable in ensuring a safe and efficient operational environment. These gratings, crafted from reinforced fiberglass, provide reliability and versatility that meet the demanding requirements across different industries. By delving into the unique features and advantages of moulded gratings, we can better understand why they stand out as an optimal choice.

The versatility of moulded gratings allows them to be adopted in a wide range of sectors. From oil and gas platforms requiring durable walkways to food and beverage facilities needing hygienic, non-corrosive flooring solutions, the adaptability of these gratings is unparalleled. Their capacity to endure extreme temperatures and load resistance also opens avenues for use in heavy-duty operations and extreme climate conditions, further broadening their application spectrum. Industry professionals and experts consistently emphasize the significance of choosing the right materials for infrastructure, and moulded gratings are increasingly recommended due to their proven track record and performance. The industry trust they garner isn't just due to their inherent properties; rigorous testing and adherence to standards affirm their reliability. These gratings are subjected to stringent quality checks, ensuring they meet both international safety norms and specific industrial requirements. To maximize the benefits of moulded gratings, collaborating with knowledgeable suppliers and contractors is crucial. Expertise in installation techniques and understanding the unique needs of specific projects ensure that the full potential of moulded gratings is realized. This collaboration also facilitates the identification of the most suitable grating specifications, considering factors such as load-bearing capacity, exposure conditions, and aesthetic preferences. In summary, the adoption of moulded gratings within industrial settings offers a strategic advantage through their durability, safety features, and cost-effectiveness. Whether it's for enhancing workplace safety, reducing maintenance costs, or supporting sustainability initiatives, moulded gratings present a compelling solution. Industry leaders continue to vouch for them as a future-proof investment that stands resilient against the challenges posed by demanding environmental and operational conditions.

The versatility of moulded gratings allows them to be adopted in a wide range of sectors. From oil and gas platforms requiring durable walkways to food and beverage facilities needing hygienic, non-corrosive flooring solutions, the adaptability of these gratings is unparalleled. Their capacity to endure extreme temperatures and load resistance also opens avenues for use in heavy-duty operations and extreme climate conditions, further broadening their application spectrum. Industry professionals and experts consistently emphasize the significance of choosing the right materials for infrastructure, and moulded gratings are increasingly recommended due to their proven track record and performance. The industry trust they garner isn't just due to their inherent properties; rigorous testing and adherence to standards affirm their reliability. These gratings are subjected to stringent quality checks, ensuring they meet both international safety norms and specific industrial requirements. To maximize the benefits of moulded gratings, collaborating with knowledgeable suppliers and contractors is crucial. Expertise in installation techniques and understanding the unique needs of specific projects ensure that the full potential of moulded gratings is realized. This collaboration also facilitates the identification of the most suitable grating specifications, considering factors such as load-bearing capacity, exposure conditions, and aesthetic preferences. In summary, the adoption of moulded gratings within industrial settings offers a strategic advantage through their durability, safety features, and cost-effectiveness. Whether it's for enhancing workplace safety, reducing maintenance costs, or supporting sustainability initiatives, moulded gratings present a compelling solution. Industry leaders continue to vouch for them as a future-proof investment that stands resilient against the challenges posed by demanding environmental and operational conditions.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024