loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative FRP Solutions from Pentair for Enhanced Performance and Durability in Water Systems

Understanding Pentair FRP A Key Component in Modern Water Treatment Solutions

In today's rapidly evolving world, the importance of effective water treatment solutions cannot be overstated. As industries strive for sustainability and efficiency, the demand for reliable materials has led to the increased usage of Fiber Reinforced Plastic (FRP) in water treatment systems. One of the prominent leaders in this domain is Pentair, a company renowned for its innovative solutions that address water quality and conservation challenges.

What is FRP?

Fiber Reinforced Plastic (FRP) is a composite material that consists of a polymer matrix reinforced with fibers, commonly glass fibers. The combination of these materials results in a lightweight, yet incredibly strong and durable product. FRP is resistant to corrosion, making it an ideal choice for applications in aggressive environments, such as water treatment and chemical processing. Its versatility allows it to be molded into various shapes and sizes, enhancing its applicability in different contexts.

Pentair’s Role in the FRP Market

Pentair has established itself as a leader in the FRP market, particularly in applications related to water treatment. The company's products are designed to meet the stringent requirements needed in water management systems. Pentair’s FRP offerings include tanks, vessels, and other components that are integral to both residential and industrial water treatment processes.

One of the key advantages of Pentair’s FRP products is their durability. These materials can withstand harsh environmental conditions, including exposure to chemicals, UV radiation, and temperature fluctuations. This resilience ensures a long service life, reducing the need for frequent replacements and thereby lowering operational costs for businesses.

Applications of Pentair FRP Products

Pentair’s FRP products are used in a variety of applications within the water treatment industry. For instance, their FRP tanks are commonly utilized in the filtration and storage of water. The lightweight nature of FRP allows for easier installation and transportation, which is particularly advantageous for large-scale projects.

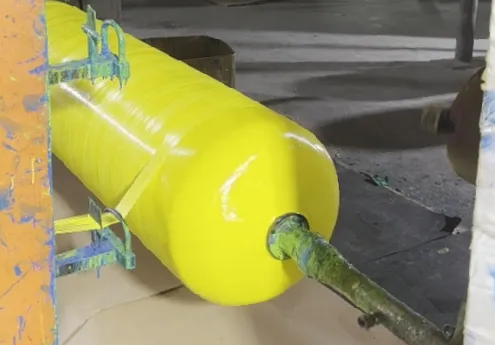

pentair frp

Moreover, Pentair’s FRP vessels are designed to handle a wide range of chemicals, making them suitable for various water treatment processes, including reverse osmosis and chemical dosing. This adaptability is crucial as industries face diverse challenges in water quality management.

In addition to water treatment, Pentair’s FRP products also find applications in other sectors, such as oil and gas, wastewater management, and industrial processes. The company's commitment to innovation has enabled it to develop specialized solutions that cater to the unique needs of these industries.

Environmental Considerations

As the world grapples with water scarcity and pollution, Pentair recognizes the need for sustainable solutions. The use of FRP in water treatment aligns with global environmental goals by promoting efficient resource management. By reducing water loss and minimizing the environmental impact of industrial processes, Pentair’s FRP products contribute to a more sustainable future.

Furthermore, FRP's resistance to corrosion means that less maintenance is required over time, resulting in less waste and reduced demand for harmful chemicals that are often used in traditional maintenance processes.

Conclusion

Pentair’s advancements in Fiber Reinforced Plastic technology represent a significant step forward in water treatment solutions. The durability, versatility, and sustainability of FRP make it an ideal material for addressing the complex challenges faced by industries today. As water scarcity and quality continue to pose critical issues globally, the innovative products developed by Pentair are crucial in paving the way towards a more sustainable and efficient future in water management.

By understanding the role and benefits of Pentair’s FRP offerings, industries can make informed choices that not only meet their operational needs but also contribute positively to the environment. In an era where water conservation is paramount, embracing advanced materials like FRP is a smart strategy for both sustainable development and operational efficiency.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024