loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits of Pentair FRP Vessels for Water Treatment Applications

Exploring Pentair FRP Vessels The Future of Water Treatment

In today's rapidly evolving industrial landscape, the demand for efficient and sustainable water treatment solutions is paramount. One of the standout innovations in this field is the use of Fiber Reinforced Plastic (FRP) vessels, particularly those manufactured by Pentair. Known for their durability, corrosion resistance, and overall performance, Pentair FRP vessels are transforming how industries manage water filtration and processing.

The Advantages of FRP Vessels

FRP vessels offer a plethora of benefits compared to traditional materials like steel or concrete. Firstly, their lightweight nature makes installation and transportation significantly easier. As industries seek to streamline operations and reduce costs, the efficiency gained from using lighter materials cannot be overstated. This is particularly important in regions where labor costs are high or transportation logistics are complex.

Secondly, FRP possesses inherent corrosion resistance, making Pentair’s vessels suitable for various applications, including chemical storage and water treatment. Traditional vessels often succumb to rust and corrosion when exposed to harsh chemicals or acidic environments. In contrast, FRP vessels maintain their structural integrity and longevity, leading to lower maintenance costs and less downtime.

Moreover, FRP materials can be engineered to provide superior insulation properties. This attribute is critical in processes where temperature control is necessary. Whether it's preventing heat loss or avoiding thermal expansion, Pentair FRP vessels can be designed to meet specific thermal requirements, ensuring optimal procedural efficiency.

Applications of Pentair FRP Vessels

Pentair FRP vessels find applications across various sectors. In municipal water treatment facilities, these vessels are essential for processes like sedimentation, filtration, and chemical dosing. Their resistance to chemical degradation makes them ideal for environments where chlorine, fluorine, or other harsh substances are involved.

pentair frp vessels

In the industrial sector, Pentair FRP vessels hold a pivotal role in chemical processing plants. They accommodate diverse chemicals without fear of degradation, which is a common concern with conventional storage solutions. This versatility makes them particularly attractive for industries such as petrochemical processing, pharmaceuticals, and food production, where stringent regulatory standards must be met.

Additionally, in the aquaculture industry, FRP vessels provide a safe and reliable environment for fish farming. Their ability to withstand corrosive elements in saltwater and freshwater environments extends their utility in maintaining healthy ecosystems for aquaculture operations.

Environmental Considerations

As industries worldwide strive for sustainability, the adoption of Pentair FRP vessels aligns with environmental goals. The manufacturing process of FRP is designed to minimize waste and energy consumption. Furthermore, the long lifespan of these vessels reduces the frequency of replacements, which directly contributes to decreased material waste.

Furthermore, Pentair emphasizes a commitment to eco-friendly practices by ensuring that their FRP vessels are recyclable. This aspect is increasingly important as many companies seek to implement circular economy principles in their operations. By choosing Pentair’s sustainable solutions, businesses do not only comply with regulations but also contribute positively to their environmental impact.

Conclusion

In conclusion, Pentair FRP vessels are flourishing as a reliable choice for modern water treatment and chemical processing applications. Their inherent advantages—lightweight, corrosion-resistant, and adaptable—position them as a forward-thinking solution to the challenges faced by various industries. As the world navigates through an era focused on sustainability and efficiency, the role of such innovative technologies cannot be underestimated.

By integrating Pentair FRP vessels into their operations, industries can ensure not only enhanced performance and cost-effectiveness but also contribute to a more sustainable future. As the water demand continues to grow and environmental regulations become stricter, the capabilities of Pentair FRP vessels will undoubtedly become even more critical in shaping the future of industrial water management.

-

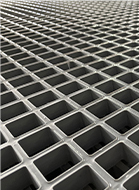

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024