loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 23, 2025 04:14

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

Pentair FRP vessels have redefined industrial storage and treatment solutions through their superior design and engineering. As a recognized leader in the water treatment and storage sector, Pentair's fiberglass reinforced plastic (FRP) vessels offer a remarkable blend of durability, versatility, and safety, catering to a wide array of applications. This exploration into Pentair FRP vessels unfolds the critical facets that make them a preferred choice across various industries, emphasizing their real-world applications, technical excellence, authority in manufacturing, and the trust they inspire among their users.

Beyond technical prowess, the trustworthiness of Pentair FRP vessels is evidenced by extensive real-world applications and positive customer testimonials. Companies across sectors such as petrochemicals, food and beverage, and water purification, consistently report high satisfaction levels due to the reliability and efficiency of these vessels. The alignment of product performance with client expectations fortifies Pentair’s reputation for delivering dependable and effective solutions, making them indispensable to operations that prioritize safety and reliability. Moreover, Pentair’s commitment to sustainability aligns with global environmental goals, as their FRP vessels are designed to minimize waste and energy during production while being highly recyclable at the end of their life cycle. This approach not only benefits the environment but also serves businesses looking to enhance their green credentials, thereby fostering a more sustainable operational model. In sum, Pentair FRP vessels continue to set benchmarks in the industry through a combination of expert engineering, authoritative presence, and an unwavering commitment to quality and sustainability. Their resilience in adverse conditions, coupled with their adaptability for various industrial uses, underscores their essential role in modern industrial applications. Pentair’s strategic focus on customer-centric innovations and robust production standards assures industry stakeholders of a product that not only meets but often surpasses expectations, thereby solidifying its reputation as a premium choice for specialized storage and treatment needs. For companies seeking reliable FRP solutions, Pentair represents a harmonious blend of trust and technology, ensuring that operational demands are met with precision, safety, and sustainability.

Beyond technical prowess, the trustworthiness of Pentair FRP vessels is evidenced by extensive real-world applications and positive customer testimonials. Companies across sectors such as petrochemicals, food and beverage, and water purification, consistently report high satisfaction levels due to the reliability and efficiency of these vessels. The alignment of product performance with client expectations fortifies Pentair’s reputation for delivering dependable and effective solutions, making them indispensable to operations that prioritize safety and reliability. Moreover, Pentair’s commitment to sustainability aligns with global environmental goals, as their FRP vessels are designed to minimize waste and energy during production while being highly recyclable at the end of their life cycle. This approach not only benefits the environment but also serves businesses looking to enhance their green credentials, thereby fostering a more sustainable operational model. In sum, Pentair FRP vessels continue to set benchmarks in the industry through a combination of expert engineering, authoritative presence, and an unwavering commitment to quality and sustainability. Their resilience in adverse conditions, coupled with their adaptability for various industrial uses, underscores their essential role in modern industrial applications. Pentair’s strategic focus on customer-centric innovations and robust production standards assures industry stakeholders of a product that not only meets but often surpasses expectations, thereby solidifying its reputation as a premium choice for specialized storage and treatment needs. For companies seeking reliable FRP solutions, Pentair represents a harmonious blend of trust and technology, ensuring that operational demands are met with precision, safety, and sustainability.

Share

Latest news

-

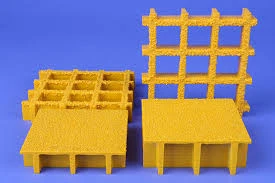

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024