loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Plastic Bar Grating Solutions for Versatile Applications and Enhanced Durability

Understanding Plastic Bar Grating Applications and Benefits

Plastic bar grating, a versatile and durable material, has gained prominence in various industries due to its unique properties and advantages. This non-metallic alternative to traditional metal gratings offers a range of benefits, making it an ideal choice for numerous applications.

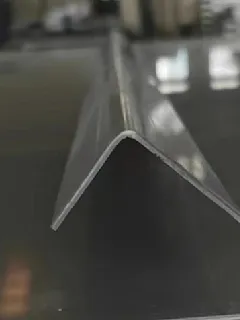

What is Plastic Bar Grating?

Plastic bar grating is a type of flooring or structural component made from molded or extruded plastic, often reinforced with fiberglass. This combination results in a lightweight, strong, and corrosion-resistant product. Typical manufacturing materials include polyvinyl chloride (PVC), polyamide (nylon), and fiberglass reinforced plastics (FRP). The grating is available in various configurations, including different bar sizes and spacing, catering to specific load-bearing requirements and surface characteristics.

Benefits of Plastic Bar Grating

1. Corrosion Resistance One of the most significant advantages of plastic bar grating is its resistance to corrosion. Unlike metal gratings that can rust and deteriorate over time when exposed to harsh environmental conditions, plastic grating remains unaffected by chemicals, saltwater, and moisture. This makes it an ideal choice for industries such as wastewater treatment, marine applications, and chemical processing.

2. Lightweight and Easy to Handle Plastic bar grating is considerably lighter than metal alternatives, which simplifies installation and reduces labor costs. Its lightweight nature allows for easier transport and handling, making it a practical choice for projects requiring frequent relocation or modification.

3. Safety Features Many plastic grating products feature slip-resistant surfaces, which enhance safety in environments prone to spills or slippery conditions. This is crucial in industrial settings, walkways, and stairs, where accidents could lead to severe injuries.

4. Customization Options Manufacturers offer a wide range of customizations for plastic bar grating. Customers can select from various colors, sizes, and configurations to meet specific project needs. This flexibility allows designers and engineers to incorporate gratings seamlessly into their projects, ensuring aesthetics and functionality are prioritized.

plastic bar grating

5. Low Maintenance With its inherent resistance to corrosion and staining, plastic bar grating requires minimal maintenance compared to metal systems. This saves both time and money over the product's lifespan, as periodic inspections and repairs are significantly reduced.

Common Applications

Plastic bar grating is utilized in numerous applications across different sectors. Its resistance to chemicals and durability makes it a favored choice for

- Industrial Flooring Factories and manufacturing facilities often use plastic grating for walkways, platforms, and machinery bases where chemical exposure is a concern.

- Water Treatment Facilities Due to its corrosion resistance, plastic bar grating is extensively used in water treatment plants, providing safe access over tanks and channels.

- Marine Environments The marine industry employs plastic grating on docks, piers, and boat ramps where exposure to saltwater is common.

- Agriculture and Horticulture Farmers and greenhouse operators use plastic grating for drainage systems and raised beds, where moisture resistance is essential.

Conclusion

Plastic bar grating is a robust, versatile solution that addresses many industrial challenges. Its unique properties, including corrosion resistance, lightweight design, and low maintenance requirements, make it an increasingly popular alternative to traditional metal gratings. With ongoing advancements in material science, the future of plastic bar grating looks promising, paving the way for even more innovative applications across diverse industries. Whether for safety, functionality, or aesthetics, plastic bar grating is a wise investment for any forward-looking project.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024