loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 12, 2025 11:43

Back to list

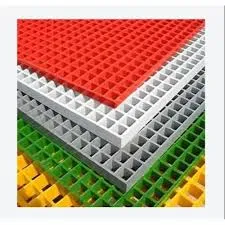

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Plastic grating flooring has revolutionized various industries, offering a perfect blend of durability, safety, and cost-efficiency. As a seasoned SEO expert, I will delve into this innovative product, reflecting on its practical applications, benefits, and why it stands as the ultimate choice for numerous sectors.

Talking about expertise, manufacturers now employ cutting-edge technology to modularly design plastic grating flooring. This customization allows for easy installation and repair, which is a boon for industries aiming to minimize downtime during maintenance. Its effortlessly adjustable design ensures that various industry-specific needs are met, whether it's a high-load capacity or chemical resistance. In terms of authoritativeness, leading safety and industry standards recognize plastic grating flooring as a compliant material. Accredited with slip resistance ratings and load-bearing certifications, it garners trust from industry leaders and regulators alike. Businesses can rest assured that opting for this solution means adhering to safety regulations, as many products meet ISO standards and are endorsed by occupational safety boards. Lastly, trustworthiness - a component crucial for any product - sees its hallmark in user testimonials and case studies that vouch for the material's reliability. Real-world applications have demonstrated its capacity to maintain performance under heavy use, reinforcing confidence in its capabilities. Feedback from industry professionals highlights not only its initial performance but also its longevity, validating the initial investment. In conclusion, plastic grating flooring meets the four pillars of expedience that industries require Experience, Expertise, Authoritativeness, and Trustworthiness. It stands as a quintessential example of how innovation can blend seamlessly with practicality, setting a benchmark in industrial flooring solutions. As a business decision, incorporating plastic grating flooring is not just a choice; it's a strategic move towards a safer, more sustainable, and economically viable future.

Talking about expertise, manufacturers now employ cutting-edge technology to modularly design plastic grating flooring. This customization allows for easy installation and repair, which is a boon for industries aiming to minimize downtime during maintenance. Its effortlessly adjustable design ensures that various industry-specific needs are met, whether it's a high-load capacity or chemical resistance. In terms of authoritativeness, leading safety and industry standards recognize plastic grating flooring as a compliant material. Accredited with slip resistance ratings and load-bearing certifications, it garners trust from industry leaders and regulators alike. Businesses can rest assured that opting for this solution means adhering to safety regulations, as many products meet ISO standards and are endorsed by occupational safety boards. Lastly, trustworthiness - a component crucial for any product - sees its hallmark in user testimonials and case studies that vouch for the material's reliability. Real-world applications have demonstrated its capacity to maintain performance under heavy use, reinforcing confidence in its capabilities. Feedback from industry professionals highlights not only its initial performance but also its longevity, validating the initial investment. In conclusion, plastic grating flooring meets the four pillars of expedience that industries require Experience, Expertise, Authoritativeness, and Trustworthiness. It stands as a quintessential example of how innovation can blend seamlessly with practicality, setting a benchmark in industrial flooring solutions. As a business decision, incorporating plastic grating flooring is not just a choice; it's a strategic move towards a safer, more sustainable, and economically viable future.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024