loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ro frp vessel

Understanding Reinforced Plastic (FRP) Vessels An Overview

Reinforced Plastic (FRP) vessels have emerged as a significant innovation in various industrial applications due to their unique properties and advantages over traditional materials. These composite materials, typically combining fiberglass with a resin matrix, provide a robust solution for industries requiring corrosion resistance, lightweight design, and high strength.

Understanding Reinforced Plastic (FRP) Vessels An Overview

Additionally, the lightweight nature of FRP vessels contributes to their practicality. Compared to traditional materials like steel, which can be much heavier, FRP offers a significant reduction in weight without compromising strength. This lightweight property allows for easier transportation and installation, reducing overall construction and operational costs. In many cases, this advantage can also lead to reduced structural support requirements, further lowering the costs associated with construction and infrastructure.

ro frp vessel

The versatility of FRP in design is another compelling feature. Vessels can be easily molded into various shapes and sizes tailored to specific requirements. This adaptability allows engineers and designers to create custom solutions that meet particular site or operational constraints. As a result, FRP vessels can be utilized in diverse applications, ranging from storage tanks to pressure vessels in high-temperature environments.

Moreover, advancements in manufacturing technologies have improved the quality and performance of FRP vessels. Techniques like the use of sophisticated resin systems and reinforcement processes ensure that these vessels not only meet but exceed industry standards. The capability to engineer specific properties into the material, such as enhanced thermal resistance or improved mechanical strength, further broadens the potential applications of FRP in industries like aerospace, automotive, and marine.

Environmental considerations play a significant role in the growing acceptance of FRP vessels. With increasing emphasis on sustainability and eco-friendly practices, the use of long-lasting materials like FRP reduces waste generation from frequent replacements of traditional materials. Furthermore, many FRP vessels are designed to be recyclable, contributing to the circular economy.

In conclusion, FRP vessels represent a fusion of innovation and practicality, offering unparalleled advantages over conventional materials. Their corrosion resistance, lightweight nature, design flexibility, and environmental benefits make them an essential choice across various industries. As technology continues to advance, the application and efficiency of FRP vessels are expected to enhance even further, paving the way for more sustainable practices in industrial production and resource management. The future of FRP technology looks promising, and it will undoubtedly play a crucial role in shaping the future of industrial vessels.

-

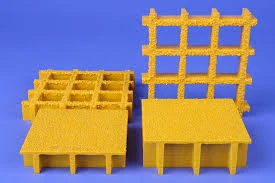

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024