loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Specifications for SMC Panel Tanks and Their Key Features and Benefits

Understanding SMC Panel Tank Specifications

SMC panel tanks, constructed from sheet molding compound (SMC), have gained significant popularity in various industries for their durability, cost-effectiveness, and ease of installation. This article will explore the specifications of SMC panel tanks, focusing on their construction, benefits, and common applications.

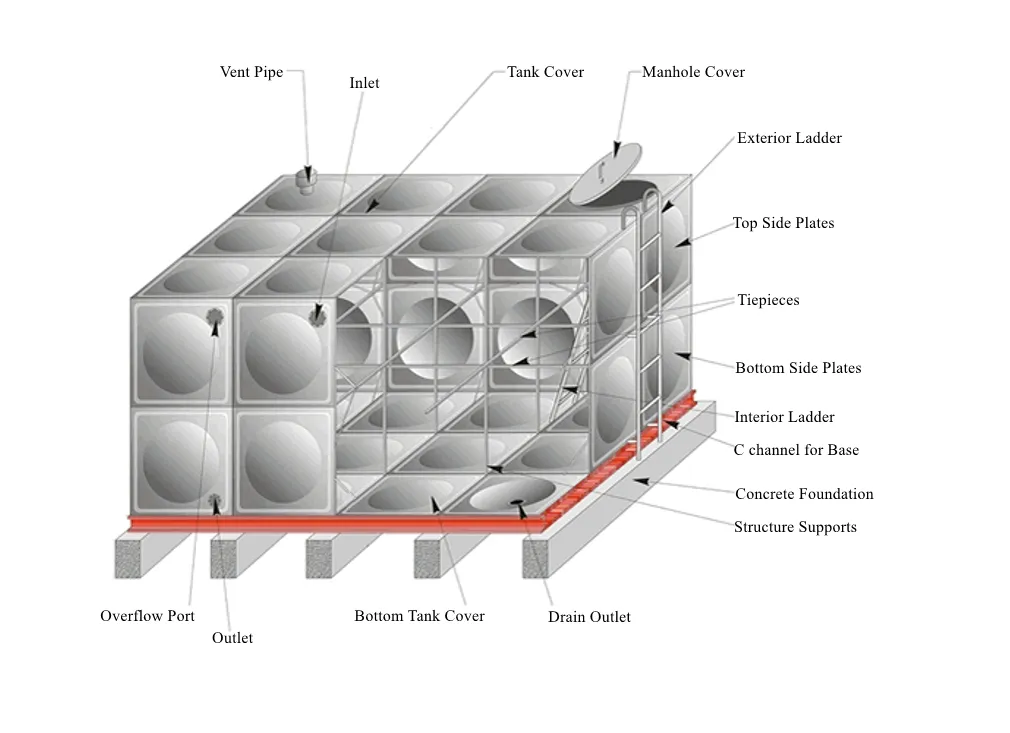

Construction and Materials

SMC panel tanks are fabricated using reinforced fiberglass materials that consist of a thermosetting resin base. The panels, which are generally made from a combination of fiberglass and polyester resin, exhibit exceptional strength and corrosion resistance. These properties make SMC tanks suitable for storing water, chemicals, and various liquids in diverse environments.

The standard thickness of SMC panels typically ranges from 4mm to 10mm, depending on the tank size and application requirements. This thickness ensures that the tank can withstand both internal pressure and external environmental conditions. Additionally, SMC tanks utilize high-quality seals and gaskets that prevent leakage and ensure long-term performance.

One of the significant advantages of SMC panel tanks is their modular construction. The individual panels can be assembled on-site, allowing for flexibility in size and shape, which is particularly beneficial in areas with space constraints. Standard sizes range from small tanks of 1,000 liters to larger capacities exceeding 1 million liters.

Durability and Maintenance

SMC panel tanks are designed to offer superior durability. They are resistant to UV rays, acids, and other corrosive substances, making them ideal for industrial applications. Unlike metal tanks, SMC tanks do not rust or corrode, which reduces maintenance costs over time. Moreover, the smooth inner surface of these tanks minimizes sediment buildup, ensuring a cleaner and healthier environment for water storage.

Maintenance of SMC panel tanks is straightforward. Unlike traditional concrete or metal tanks that may require frequent inspections for rust or structural integrity, SMC tanks primarily need regular cleaning and inspections to ensure that seals remain intact and that no damages occur due to external factors.

smc panel tank specifications

Applications

SMC panel tanks are versatile in their applications

. They are widely used in1. Water Treatment Plants Due to their ability to store large volumes of water and their resistance to contaminants, SMC tanks are suitable for both potable water storage and wastewater treatment processes.

2. Chemical Storage Industries that handle corrosive chemicals benefit from SMC tanks because of their resistance to chemical reactions, ensuring safer storage.

3. Fire Protection Systems Many fire safety systems incorporate SMC panel tanks for their efficient and reliable water storage capabilities during emergencies.

4. Agriculture SMC tanks are also used for irrigation purposes, providing farmers with a reliable source of water.

Conclusion

In summary, SMC panel tanks present a robust, versatile, and cost-effective solution for various storage needs. Their exceptional strength, durability, and low maintenance requirements make them a preferred choice across multiple industries. As technology continues to advance, we can expect further innovations in SMC tank design and functionality, paving the way for even more efficient storage solutions in the future. Whether for industrial, agricultural, or municipal use, understanding the specifications of SMC panel tanks is crucial for selecting the right solution to meet specific storage requirements.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024