loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 28, 2025 02:52

Back to list

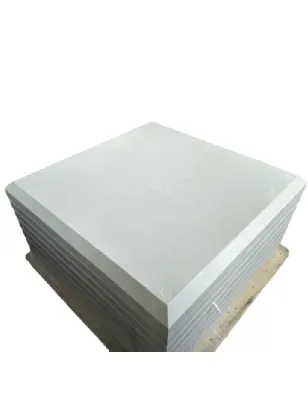

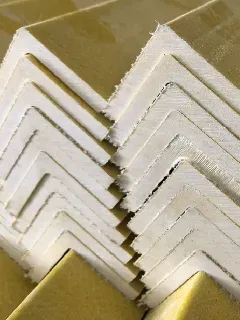

smc panel tank

Choosing the right SMC panel tank specifications can significantly impact the efficiency and suitability of the water storage system for any project, whether it be an industrial facility or a residential complex. SMC (Sheet Moulding Compound) panel tanks are renowned for their durability, versatility, and lightweight properties, making them a popular choice across various sectors. Here's an in-depth exploration of why these tanks are at the forefront of water storage solutions and what sets them apart.

Safety is a paramount consideration in water storage solutions, and it's here that the engineering of SMC panel tanks really shines. The structural integrity of these tanks adheres to rigorous international standards, offering peace of mind concerning mechanical stability under various stress conditions, such as water pressure or environmental forces like wind. Manufacturers commonly test these tanks under extreme circumstances, further affirming their robustness and reliability. For potential buyers prioritizing environmental sustainability, SMC panel tanks are a compelling choice. The manufacturing process of these tanks is energy-efficient, and the materials involved are non-toxic and recyclable. Opting for SMC tanks can align with broader sustainability goals, fulfilling corporate responsibility requirements or green building certifications. The maintenance of SMC panel tanks is just as efficient as their installation. The panel design allows for easy access to any internal surface, facilitating inspection and cleaning procedures without significant downtime. Furthermore, in the rare event of damage occurring, the panelized system means that only specific sections need replacement or repair, minimizing costs and service interruption. In conclusion, the specifications of SMC panel tanks give them a distinct edge over many traditional water storage systems. From their corrosion resistance and thermal insulation to easy installation and maintenance, they represent a modern, high-performance solution in both large-scale industrial applications and smaller residential projects. For those seeking a reliable, customizable, and environmentally friendly water storage option, SMC panel tanks offer a robust and versatile choice, backed by engineering excellence and a commitment to quality. Choosing the right specifications depends greatly on the intended use, available space, and required capacity. Engaging with an experienced supplier who can provide guidance tailored to specific project needs is advisable. This partnership can ensure that the full potential of SMC panel tanks is realized, delivering on all fronts of performance and reliability.

Safety is a paramount consideration in water storage solutions, and it's here that the engineering of SMC panel tanks really shines. The structural integrity of these tanks adheres to rigorous international standards, offering peace of mind concerning mechanical stability under various stress conditions, such as water pressure or environmental forces like wind. Manufacturers commonly test these tanks under extreme circumstances, further affirming their robustness and reliability. For potential buyers prioritizing environmental sustainability, SMC panel tanks are a compelling choice. The manufacturing process of these tanks is energy-efficient, and the materials involved are non-toxic and recyclable. Opting for SMC tanks can align with broader sustainability goals, fulfilling corporate responsibility requirements or green building certifications. The maintenance of SMC panel tanks is just as efficient as their installation. The panel design allows for easy access to any internal surface, facilitating inspection and cleaning procedures without significant downtime. Furthermore, in the rare event of damage occurring, the panelized system means that only specific sections need replacement or repair, minimizing costs and service interruption. In conclusion, the specifications of SMC panel tanks give them a distinct edge over many traditional water storage systems. From their corrosion resistance and thermal insulation to easy installation and maintenance, they represent a modern, high-performance solution in both large-scale industrial applications and smaller residential projects. For those seeking a reliable, customizable, and environmentally friendly water storage option, SMC panel tanks offer a robust and versatile choice, backed by engineering excellence and a commitment to quality. Choosing the right specifications depends greatly on the intended use, available space, and required capacity. Engaging with an experienced supplier who can provide guidance tailored to specific project needs is advisable. This partnership can ensure that the full potential of SMC panel tanks is realized, delivering on all fronts of performance and reliability.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024