loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

stainless steel filter vessel

Understanding Stainless Steel Filter Vessels

Stainless steel filter vessels play a critical role in various industries, serving as essential components in the filtration process. Their robust design, durability, and resistance to corrosion make them ideal for handling a wide range of fluids, including chemicals, pharmaceuticals, and food products. In this article, we will explore the advantages of stainless steel filter vessels, their applications, and key considerations when selecting one for your needs.

One of the primary benefits of stainless steel filter vessels is their exceptional resistance to corrosion and rust. Unlike other materials, stainless steel maintains its integrity in harsh environments, making it suitable for applications involving aggressive chemicals or extreme temperatures. This durability extends the lifespan of the vessel, leading to lower maintenance and replacement costs over time.

Another significant advantage is the high level of hygiene offered by stainless steel. In industries such as food and beverage, pharmaceuticals, and cosmetics, maintaining sanitary conditions is paramount. Stainless steel filter vessels are easy to clean and sanitize, preventing contamination and complying with stringent industry regulations. Their smooth surface finish reduces the risk of microbial growth, ensuring product safety.

stainless steel filter vessel

In terms of design, stainless steel filter vessels can be customized to meet specific operational requirements. They are available in various sizes, configurations, and filtration media options, allowing industries to select solutions tailored to their unique processes. Common designs include bag filters, cartridge filters, and self-cleaning filters. Moreover, many vessels come equipped with advanced features such as pressure gauges, level indicators, and automatic backwashing systems, enhancing their operational efficiency and effectiveness.

Applications of stainless steel filter vessels span numerous sectors. In the chemical industry, they are used for the filtration of solvents, acids, and other aggressive substances. In the pharmaceutical sector, these vessels play a critical role in the production of sterile products by ensuring that impurities and contaminants are effectively removed. Additionally, in water treatment facilities, stainless steel filters are essential for removing particulates and other impurities from drinking water.

When choosing a stainless steel filter vessel, several factors should be considered. First, assess the type of fluid being filtered and its properties, such as viscosity and temperature. Ensure that the selected vessel can handle these characteristics effectively. Next, evaluate the required filtration level and choose an appropriate filtration media based on the application. Finally, consider the vessel's capacity and flow rate to ensure it meets your operational demands.

In conclusion, stainless steel filter vessels are indispensable tools across a myriad of industries due to their exceptional durability, hygiene, and versatility. By understanding their advantages and applications, as well as key selection criteria, businesses can make informed decisions that enhance their filtration processes and ensure optimal product quality. Whether for industrial use or food production, stainless steel filter vessels will continue to be a reliable choice for effective filtration solutions.

-

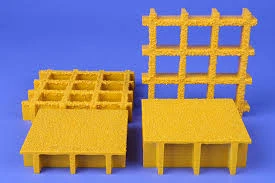

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024