loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 26, 2025 07:14

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

Starlite FRP vessels have emerged as a transformative solution in the industry of fluid storage and processing, combining innovative design with unparalleled durability. For businesses focused on scaling operations, efficiency, and safety, picking the right FRP vessel is crucial. Starlite's offerings stand as a testament to cutting-edge engineering and reliability.

Furthermore, the adaptation of automated manufacturing processes in producing these vessels ensures precision and consistency in each unit. This technological advancement adds a layer of expertise, ensuring that each vessel not only meets but exceeds industry standards. The employment of state-of-the-art machinery reflects Starlite's commitment to innovation and leadership in fiberglass vessel manufacturing. For experts in environmental compliance, it is equally important to note that Starlite FRP vessels are eco-friendly. The production process minimizes waste, aligning with global sustainability goals. Additionally, the materials used in these vessels are recyclable, offering a solution that supports green initiatives and positions businesses ahead in addressing ecological concerns. Customer reviews and industry testimonials vouch for the credibility and reliability of Starlite FRP vessels. Clients frequently highlight the low maintenance requirements and long-term cost benefits as key reasons for their satisfaction. This positive feedback not only enhances the product's trustworthiness but also underscores the brand's commitment to creating value for its customers. Investing in Starlite FRP vessels is a strategic move towards fortifying operational infrastructure with reliable and efficient storage solutions. Companies in sectors like pharmaceuticals, agriculture, and petrochemicals find these vessels indispensable for safely handling sensitive and volatile substances. In conclusion, Starlite FRP vessels are more than just storage units; they are a comprehensive solution backed by innovation, expertise, and a commitment to quality. As industries face increasing demands for efficiency and sustainability, making informed decisions about equipment like Starlite FRP vessels is essential. Businesses looking to maintain a competitive edge and safeguard their operational credibility would do well to incorporate these advanced vessels into their workflow.

Furthermore, the adaptation of automated manufacturing processes in producing these vessels ensures precision and consistency in each unit. This technological advancement adds a layer of expertise, ensuring that each vessel not only meets but exceeds industry standards. The employment of state-of-the-art machinery reflects Starlite's commitment to innovation and leadership in fiberglass vessel manufacturing. For experts in environmental compliance, it is equally important to note that Starlite FRP vessels are eco-friendly. The production process minimizes waste, aligning with global sustainability goals. Additionally, the materials used in these vessels are recyclable, offering a solution that supports green initiatives and positions businesses ahead in addressing ecological concerns. Customer reviews and industry testimonials vouch for the credibility and reliability of Starlite FRP vessels. Clients frequently highlight the low maintenance requirements and long-term cost benefits as key reasons for their satisfaction. This positive feedback not only enhances the product's trustworthiness but also underscores the brand's commitment to creating value for its customers. Investing in Starlite FRP vessels is a strategic move towards fortifying operational infrastructure with reliable and efficient storage solutions. Companies in sectors like pharmaceuticals, agriculture, and petrochemicals find these vessels indispensable for safely handling sensitive and volatile substances. In conclusion, Starlite FRP vessels are more than just storage units; they are a comprehensive solution backed by innovation, expertise, and a commitment to quality. As industries face increasing demands for efficiency and sustainability, making informed decisions about equipment like Starlite FRP vessels is essential. Businesses looking to maintain a competitive edge and safeguard their operational credibility would do well to incorporate these advanced vessels into their workflow.

Share

Latest news

-

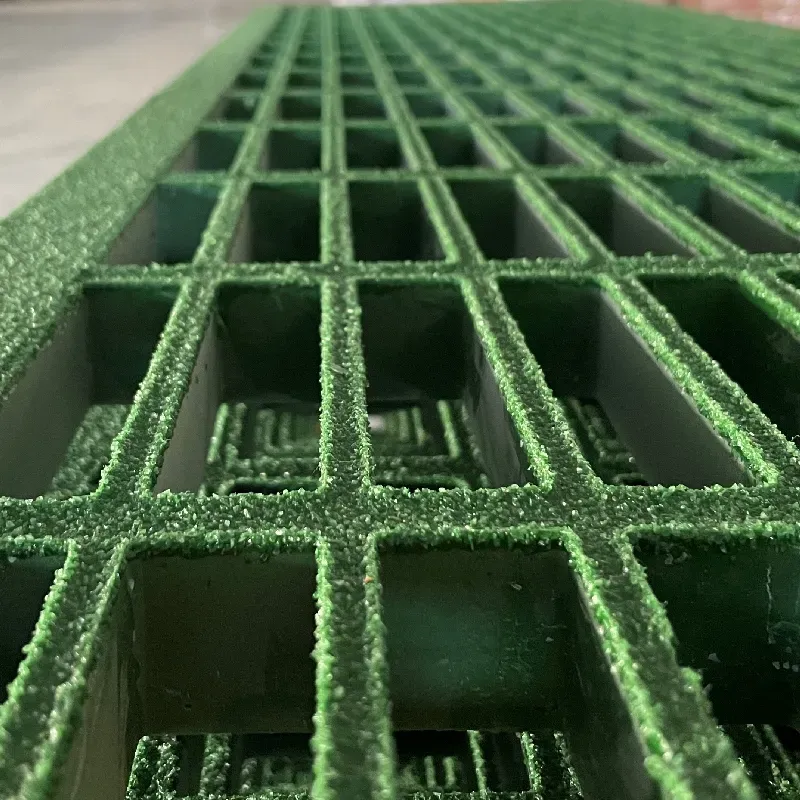

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024