loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Guide to Common Steel Channel Sizes and Specifications for Construction

Understanding Steel C Channel Sizes Properties and Applications

When it comes to construction and structural design, the choice of materials is crucial to ensuring safety, durability, and functionality. Among the various options available, steel is the most significant material due to its high strength-to-weight ratio, versatility, and durability. One specific type of steel profile widely used in construction is the C channel, often referred to as a C-section or C-beam. A C channel is a piece of structural steel that has a U-shaped cross-section and is commonly used in a variety of applications.

What Are Steel C Channels?

Steel C channels are structural steel members that feature a cross-section resembling the letter C. The dimensions of C channels are defined by their height, width, thickness, and the weight per unit length. These channels are widely utilized in construction due to their ability to bear loads and provide structural support in various applications such as framing, bracing, and as supports for walls and roofs.

Steel C Channel Sizes

The sizes of steel C channels can vary based on standards set by various organizations, but some common sizes fall within specific ranges. Typically, the size of a C channel is specified by its height (the vertical leg) and width (the horizontal leg). For instance, a C channel might be labeled as C 10 x 15, indicating a height of 10 inches and a weight of 15 pounds per foot. The dimensions and specifications of steel C channels are often standardized, allowing for easy identification and selection.

Common sizes of steel C channels can include

- 4 x 5.4 (Height 4 inches, Weight 5.4 lbs/ft) - 6 x 13.2 (Height 6 inches, Weight 13.2 lbs/ft) - 8 x 10.8 (Height 8 inches, Weight 10.8 lbs/ft) - 10 x 15 (Height 10 inches, Weight 15 lbs/ft) - 12 x 20 (Height 12 inches, Weight 20 lbs/ft)

These are just a few examples, and the actual size range can expand significantly depending on the specific requirements and standards adhered to in different regions or industries.

Properties of Steel C Channels

The properties of steel C channels make them an excellent choice for many construction applications

. Here are some inherent characteristicssteel chs sizes

1. Strength and Stiffness C channels exhibit higher tensile and compressive strength, making them ideal for load-bearing applications.

2. Weight Since C channels are formed from relatively lightweight materials, they contribute to lower transportation and handling costs.

3. Versatility The shape and design of C channels allow them to be used in various applications, from simple frames to complex infrastructures.

4. Corrosion Resistance When properly coated or treated, steel C channels can resist corrosion, enhancing their durability in harsh environments.

5. Ease of Fabrication C channels can be easily cut, drilled, or welded, allowing for greater flexibility in custom fabrication for specific project requirements.

Applications of Steel C Channels

Steel C channels are used extensively in various construction and engineering applications, including

- Structural Framing C channels are commonly used in building frames and supports, enabling the construction of both residential and commercial structures. - Bracing They serve as bracing elements in steel buildings, providing stability against lateral forces such as wind and seismic activities.

- Support Systems C channels can function as supports for heavy machinery and equipment, ensuring secure mounting points.

- Transportation In the transportation sector, they are used in the construction of trailers, truck bodies, and railway supports.

In conclusion, steel C channels offer a reliable and versatile solution for various construction needs. Understanding the different sizes and properties of C channels can aid engineers and architects in making informed decisions for their projects. With their adaptability and strength, C channels continue to play a pivotal role in modern construction, contributing to safe and robust structural designs. Whether used in residential buildings or large-scale industrial projects, the importance of selecting the right steel C channel size cannot be overstated, as it directly impacts the overall performance and longevity of the structure.

-

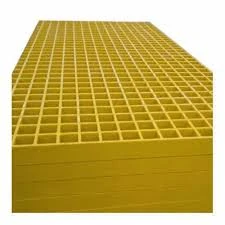

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024