loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

structural frp

Understanding Structural FRP An Overview

Fiber Reinforced Polymer (FRP) composites have gained significant attention in the construction and engineering sectors due to their unique properties and versatile applications. As a material that combines the high strength of fibers with the lightweight, corrosion-resistant, and moldable qualities of polymers, FRP has revolutionized the way structural components are designed, constructed, and maintained.

The Composition and Advantages of FRP

FRP composites typically consist of a polymer matrix reinforced with fibers such as glass, carbon, or aramid. The choice of fiber determines the mechanical properties of the final product, allowing for tailor-made solutions that meet specific engineering needs. For example, glass fibers provide excellent durability and are cost-effective, while carbon fibers offer superior strength-to-weight ratios, making them ideal for high-performance applications.

One of the most compelling advantages of FRP is its resistance to environmental degradation. Unlike traditional materials such as steel, which can corrode in aggressive environments, FRP remains unaffected by moisture, chemicals, and UV light. This characteristic not only prolongs the lifespan of structures but also reduces the need for frequent maintenance and repairs, leading to significant cost savings over time.

Additionally, the lightweight nature of FRP translates into easier handling and installation. Structures made from FRP can often be assembled more rapidly, reducing labor costs and minimizing construction time. Furthermore, the flexibility in design offered by FRP allows engineers to create more complex and aesthetically pleasing structures that were previously challenging to achieve with conventional materials.

Applications of Structural FRP

The applications of FRP are extensive, ranging from bridge construction to building facades and even seismic retrofitting. In the civil engineering sector, FRP is frequently used in bridges, where its high strength-to-weight ratio allows for longer spans and reduced structural dead weight. This makes it an excellent choice for both new constructions and rehabilitation of existing structures.

structural frp

In addition to bridges, FRP is increasingly being utilized in building infrastructure, such as beams, columns, and slabs. The material's resistance to corrosion makes it ideal for use in harsh environments, including marine applications and chemical plants where exposure to aggressive substances is common.

Another important application of FRP is in the field of seismic retrofitting. By wrapping existing columns and beams with FRP materials, engineers can enhance their load-bearing capacity and ductility, significantly improving the structure’s ability to withstand seismic events. This process can extend the lifespan of older buildings and protect them from potential earthquake damage with minimal disruption to occupants.

Challenges and Future Directions

Despite its many benefits, the adoption of FRP in structural engineering does face challenges. The initial costs of FRP materials can be higher than traditional options, which may deter some project managers and stakeholders. However, this initial investment is often offset by the long-term savings generated through reduced maintenance costs and extended operational lifespans.

Furthermore, more research is needed to refine manufacturing processes and develop predictive models for the performance of FRP in various conditions. The establishment of standardized design codes and guidelines will also play a crucial role in promoting the widespread use of FRP materials across the industry.

Looking ahead, the future of structural FRP appears promising. Innovations in material science and engineering practices are likely to enhance the capabilities of FRP composites, making them even more viable in high-demand applications. As sustainability becomes a central theme in construction practices, the use of FRP can contribute to environmentally friendly designs by reducing material wastage and extending the life of structures.

Conclusion

In summary, Fiber Reinforced Polymer stands at the forefront of modern engineering materials, offering a blend of strength, durability, and flexibility. Its diverse applications and benefits make it a valuable asset in the construction industry. As ongoing research continues to address existing challenges, the potential for FRP to transform structural design and construction practices will undoubtedly grow, marking a significant step forward in building resilient and sustainable infrastructure for the future.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

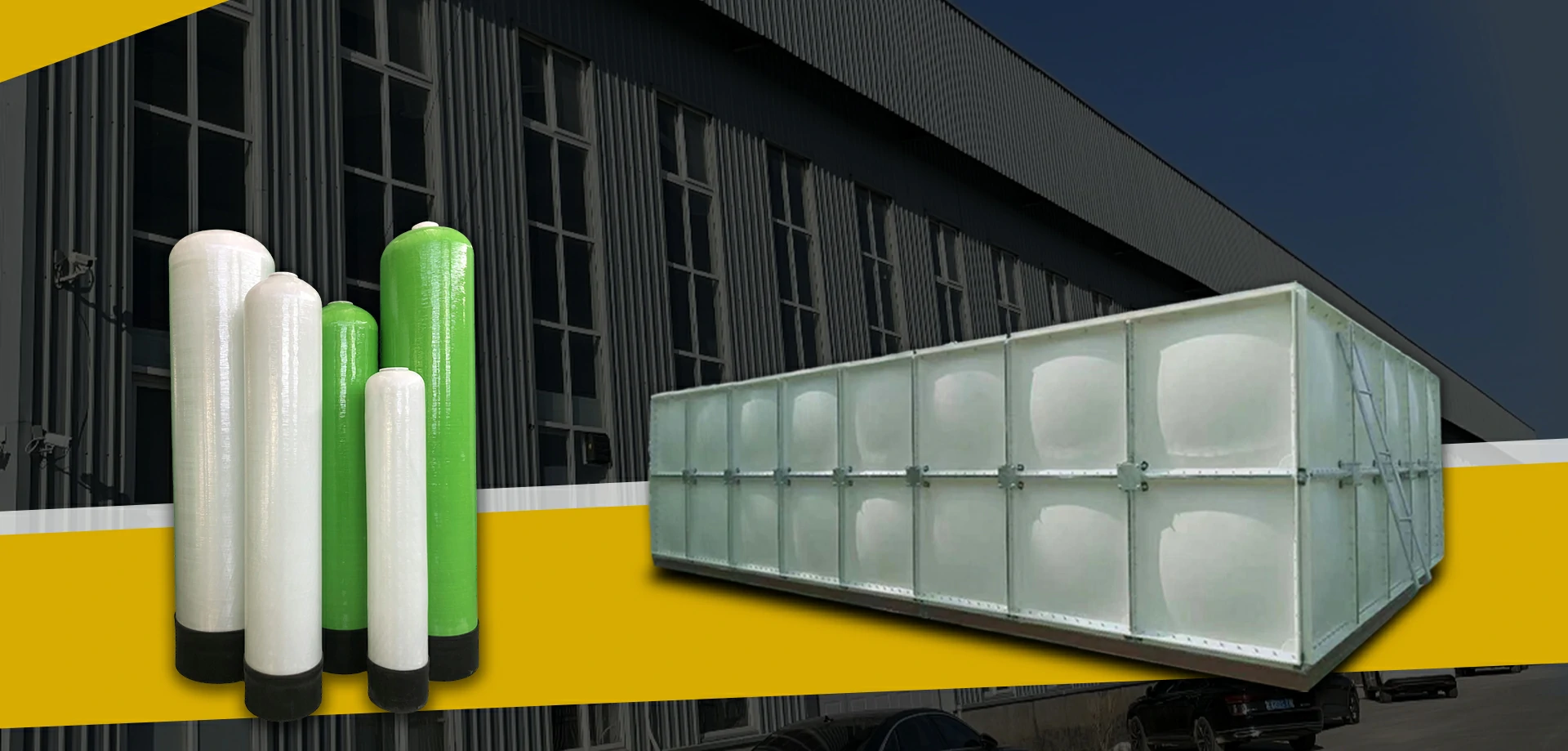

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024