loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

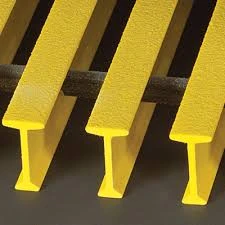

structural frp

Structural FRP Revolutionizing Construction and Design

Fiber Reinforced Polymer (FRP) is rapidly transforming the fields of construction and structural engineering. This innovative material, made from a polymer matrix reinforced with fibers (commonly glass, carbon, or aramid), offers a remarkable combination of strength, durability, and versatility. As the need for sustainable and resilient infrastructure grows, FRP presents a compelling alternative to traditional materials like steel and concrete.

What is Structural FRP?

Structural FRP consists of a composite matrix that combines the lightweight characteristics of polymers with the high strength and stiffness of fibers. These composites can be molded into complex shapes and used in a wide array of applications, from bridges and buildings to marine structures and wind turbines. The inherent properties of FRP make it particularly advantageous in environments where corrosion resistance, low maintenance, and high tensile strength are paramount.

Unsung Benefits of FRP in Construction

One of the most significant benefits of FRP is its impressive corrosion resistance. Unlike steel, which can degrade in harsh environments, FRP maintains its structural integrity over time. This is particularly important in structures exposed to seawater, chemical plants, or areas with high moisture content. The addition of FRP can extend the lifespan of constructions and reduce maintenance costs significantly.

Moreover, FRP is exceptionally lightweight—about one-fourth the weight of steel—yet offers comparable, if not superior, strength. This characteristic allows for easier handling and installation, reducing labor costs and construction time. For example, in seismic areas, using FRP as a reinforcing material in concrete structures can improve their ability to withstand earthquakes without the weight penalty associated with conventional materials.

Sustainability and Environmental Impact

structural frp

In an era increasingly focused on sustainability, the environmental footprint of construction materials is under scrutiny. FRP can be produced with less energy than traditional metals and is often manufactured using recyclable materials. Additionally, the long lifespan and low maintenance needs of FRP structures lead to less waste over time. By integrating FRP into new designs, engineers can not only enhance performance but also contribute to a greener future.

Applications of Structural FRP

The versatility of FRP has led to its adoption in various applications. In the transportation sector, FRP is used in bridge construction, where it can significantly reduce the dead load while offering resilience against environmental degradation. In the building industry, FRP reinforcements can be utilized to strengthen existing structures and improve their load-bearing capacities without extensive renovations.

Furthermore, FRP is gaining traction in the aviation and automotive industries, where weight reduction is critical for performance and fuel efficiency. The integration of FRP components in aircraft wings and car bodies showcases the material's effectiveness in enhancing performance while minimizing environmental impact.

Challenges and Future Outlook

Despite its advantages, the adoption of structural FRP is not without challenges. Higher initial costs compared to traditional materials can deter some projects. Additionally, the design and fabrication of FRP still require specialized knowledge and expertise, which may not be widely available. However, ongoing research and innovation are likely to mitigate these challenges, as advancements in manufacturing processes and material science continue to emerge.

As the construction industry evolves, the role of structural FRP will undoubtedly expand. Increased awareness of its benefits combined with a push for more sustainable practices positions FRP as a crucial player in the future of engineering. By embracing this innovative material, the industry can look forward to building stronger, more resilient, and sustainable infrastructures that meet the demands of modern society. In conclusion, structural FRP represents a significant leap forward in engineering, offering a path toward a more efficient and environmentally friendly construction approach.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024