loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 08, 2025 00:49

Back to list

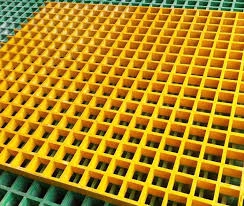

structural frp fiberglass

Structural FRP fiberglass, a material known for its robustness and versatility, has become a game-changer in the construction and manufacturing industries. Its unique properties have unlocked new possibilities for design and engineering, prompting professionals to re-evaluate traditional materials in favor of this modern alternative.

Trustworthiness is further reinforced by established case studies and endorsements from users of structural FRP fiberglass. For instance, municipalities in Europe have adopted it extensively in the refurbishment of aging public facilities, reporting improved safety records and reduced lifecycle costs. Testimonials from city planners and construction managers confirm its role as not only a cost-effective solution but also a material that contributes positively to public welfare by ensuring structural safety and reducing environmental impact. Product-wise, the range of structural FRP fiberglass applications is vast, with manufacturers offering tailored solutions for industries ranging from automotive to aerospace. In architectural applications, its versatility allows for the creation of innovative designs that are aesthetically pleasing yet structurally sound. Architects appreciate the material's ability to maintain its integrity under extreme conditions, providing flexibility in both indoor and outdoor environments. In conclusion, the rise of structural FRP fiberglass is backed by ample evidence of its practical and theoretical strengths. With growing recognition across industries, it positions itself as a pivotal material for future-proofing infrastructure and meeting evolving technical demands. Emphasizing real-world successes, scientific backing, and trustworthy endorsements, FRP fiberglass stands as a testament to modern engineering achievements. As industries continue to explore and expand its potential, it remains at the forefront of material innovation, promising a blend of durability, cost-efficiency, and environmental responsibility.

Trustworthiness is further reinforced by established case studies and endorsements from users of structural FRP fiberglass. For instance, municipalities in Europe have adopted it extensively in the refurbishment of aging public facilities, reporting improved safety records and reduced lifecycle costs. Testimonials from city planners and construction managers confirm its role as not only a cost-effective solution but also a material that contributes positively to public welfare by ensuring structural safety and reducing environmental impact. Product-wise, the range of structural FRP fiberglass applications is vast, with manufacturers offering tailored solutions for industries ranging from automotive to aerospace. In architectural applications, its versatility allows for the creation of innovative designs that are aesthetically pleasing yet structurally sound. Architects appreciate the material's ability to maintain its integrity under extreme conditions, providing flexibility in both indoor and outdoor environments. In conclusion, the rise of structural FRP fiberglass is backed by ample evidence of its practical and theoretical strengths. With growing recognition across industries, it positions itself as a pivotal material for future-proofing infrastructure and meeting evolving technical demands. Emphasizing real-world successes, scientific backing, and trustworthy endorsements, FRP fiberglass stands as a testament to modern engineering achievements. As industries continue to explore and expand its potential, it remains at the forefront of material innovation, promising a blend of durability, cost-efficiency, and environmental responsibility.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024