loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 04, 2025 05:11

Back to list

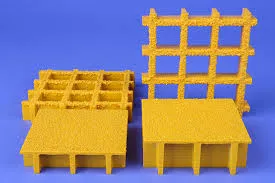

High Strength FRP Pultruded Profile Fiberglass I Beam for Construction

Unlocking the potential of structural profiles can revolutionize product development and enhance the design and functionality of various applications. In industries ranging from construction and manufacturing to aerospace and automotive, structural profiles offer a foundation upon which innovative and durable solutions are built.

Beyond industry-specific applications, the versatility of structural profiles finds its way into everyday products. From office furniture to modular shelving systems, profiles enable designs that are not only functional but also aesthetically pleasing. The ability to customize shapes and sizes empowers designers to create unique products tailored to consumer preferences, enhancing user experience and satisfaction. Real-world examples of companies successfully implementing structural profiles further illustrate their significance. Leading aerospace companies like Boeing and Airbus have continually innovated with advanced materials and designs, ensuring their aircraft remain at the forefront of the industry. In the automotive realm, Tesla's use of aluminum profiles exemplifies a commitment to lightweight design and sustainability. These industry leaders demonstrate the transformative power of strategic profile utilization. The expertise involved in designing and producing structural profiles cannot be overstated. Engineers and material scientists collaborate extensively to optimize the performance of these profiles, employing sophisticated software and testing methodologies to ensure compliance with international standards and regulations. This teamwork guarantees that every profile meets the demanding expectations of various applications, setting a benchmark for quality and reliability. Trustworthiness in structural profiles extends beyond material integrity; it encompasses ethical sourcing, sustainable production practices, and a commitment to innovation. Companies dedicated to transparency in their operations build trust with clients by demonstrating accountability and responsiveness to changing market demands. This commitment not only strengthens their market position but also fosters long-term relationships with partners and customers who value sustainability and quality. In conclusion, structural profiles are the unsung heroes of modern engineering, providing the essential support that underpins countless innovations. Their impact resonates across industries, improving efficiency, safety, and design. By maintaining a focus on expertise, authority, and trustworthiness, companies can harness the full potential of structural profiles, driving their products to new heights of success in an ever-evolving technological landscape.

Beyond industry-specific applications, the versatility of structural profiles finds its way into everyday products. From office furniture to modular shelving systems, profiles enable designs that are not only functional but also aesthetically pleasing. The ability to customize shapes and sizes empowers designers to create unique products tailored to consumer preferences, enhancing user experience and satisfaction. Real-world examples of companies successfully implementing structural profiles further illustrate their significance. Leading aerospace companies like Boeing and Airbus have continually innovated with advanced materials and designs, ensuring their aircraft remain at the forefront of the industry. In the automotive realm, Tesla's use of aluminum profiles exemplifies a commitment to lightweight design and sustainability. These industry leaders demonstrate the transformative power of strategic profile utilization. The expertise involved in designing and producing structural profiles cannot be overstated. Engineers and material scientists collaborate extensively to optimize the performance of these profiles, employing sophisticated software and testing methodologies to ensure compliance with international standards and regulations. This teamwork guarantees that every profile meets the demanding expectations of various applications, setting a benchmark for quality and reliability. Trustworthiness in structural profiles extends beyond material integrity; it encompasses ethical sourcing, sustainable production practices, and a commitment to innovation. Companies dedicated to transparency in their operations build trust with clients by demonstrating accountability and responsiveness to changing market demands. This commitment not only strengthens their market position but also fosters long-term relationships with partners and customers who value sustainability and quality. In conclusion, structural profiles are the unsung heroes of modern engineering, providing the essential support that underpins countless innovations. Their impact resonates across industries, improving efficiency, safety, and design. By maintaining a focus on expertise, authority, and trustworthiness, companies can harness the full potential of structural profiles, driving their products to new heights of success in an ever-evolving technological landscape.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024