loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Optimizing Vessel Purifier Efficiency for Enhanced Maritime Operations and Environmental Safety

Understanding Vessel Purifiers Essential Components for Marine Safety and Efficiency

In the maritime industry, the importance of maintaining fuel quality and ensuring the efficient operation of marine engines cannot be overstated. One critical technology that has emerged to address these needs is the vessel purifier. These purifiers play a vital role in facilitating the safe and efficient functioning of ships, thereby minimizing environmental impact while maximizing performance.

A vessel purifier, commonly known as a fuel oil purifier, is designed to separate impurities from fuel oil, ensuring that only clean fuel is delivered to the engine. The process of purification helps in removing water, sediments, and other contaminants that can adversely affect the engine's performance and longevity. By employing centrifugal force, these purifiers can effectively separate different densities of substances, allowing for efficient filtration and cleaner fuel.

The operational efficiency of a vessel purifier is largely dependent on its design and technology. Most modern purifiers utilize a combination of gravity and centrifugal forces to enhance the separation process. When fuel enters the purifier, it is directed into a rotating bowl where the high rotational speed creates a centrifugal field. Heavier particles, such as sludge and water, are pushed outward to settle at the bottom of the bowl, while the cleaner fuel rises to the top. The separation is further enhanced by the use of specialized coalescing elements that promote the agglomeration of smaller droplets, improving the overall efficacy of the purification process.

vessel purifier

One significant advantage of vessel purifiers is their contribution to compliance with international environmental regulations, such as MARPOL Annex VI, which regulates air pollution from ships. By ensuring that only high-quality fuel is used in the combustion process, these purifiers help reduce harmful emissions such as sulfur oxides (SOx) and particulate matter, contributing to cleaner marine operations.

Furthermore, regular maintenance and accurate operation of vessel purifiers are crucial for ensuring their effectiveness. Operators must monitor the flow rate, pressure, and temperature, as well as schedule timely cleaning and servicing of the purifier. Neglecting these tasks can lead to reduced efficiency, increased fuel consumption, or even engine damage due to impurities reaching the engine.

The implementation of advanced technologies such as automated controls and digital monitoring systems in vessel purifiers has significantly improved their reliability and ease of use. These innovations allow for real-time monitoring of the purification process, enabling operators to make informed decisions and adjustments on-the-fly. Such technologies not only enhance safety but also contribute to cost savings by reducing fuel waste and optimizing engine performance.

In conclusion, vessel purifiers are indispensable components in the maritime industry, ensuring that fuel quality is maintained while complying with environmental regulations. Their ability to effectively separate contaminants from fuel oil enhances engine performance and longevity, making them a key aspect of marine engineering. As technology continues to advance, the role of vessel purifiers will likely grow, further solidifying their status as essential tools for ensuring safe and efficient marine operations.

-

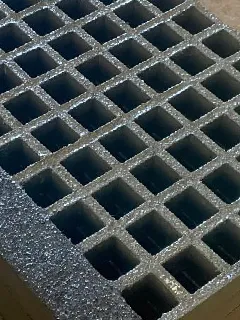

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024