loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:10

Back to list

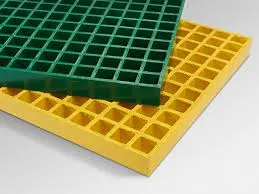

cutting frp grating

Cutting FRP (Fiber Reinforced Plastic) grating can be an intricate process that demands precision, expertise, and the right tools to achieve optimal results. When dealing with this highly durable material, understanding its unique properties becomes crucial for both effective application and maintaining its structural integrity.

In terms of expertise, elevating your skills in cutting FRP grating often involves learning through real-world experience. Invest time in understanding how different resin types and fiber orientations react to various cutting tools. This detailed knowledge can be the difference between a seamless installation and a flawed outcome that necessitates repairs or complete replacement. To ensure authoritativeness, aligning oneself with industry standards and keeping abreast of technological advancements in cutting tools and safety protocols enhances the work quality. Participating in courses or certification programs specifically tailored to composite materials can further solidify one’s standing as an authority in this field. Trustworthiness in cutting FRP grating can be conveyed through customer-focused communications. Providing clients or stakeholders with comprehensive explanations of the chosen cutting techniques and safety measures not only builds trust but also establishes clear expectations. It’s possible to bolster this trust by sharing testimonials and success stories from previous projects, reassuring potential customers of your expertise and commitment to quality. In conclusion, cutting FRP grating transcends basic craftsmanship. It combines understanding of the material, precise execution, necessary tooling, rigorous safety practices, and continued learning. Those who excel in this realm not only apply their skills to enhance project outcomes but also contribute to elevating industry standards, setting themselves apart as trusted authorities in a niche that demands both proficiency and careful attention to detail.

In terms of expertise, elevating your skills in cutting FRP grating often involves learning through real-world experience. Invest time in understanding how different resin types and fiber orientations react to various cutting tools. This detailed knowledge can be the difference between a seamless installation and a flawed outcome that necessitates repairs or complete replacement. To ensure authoritativeness, aligning oneself with industry standards and keeping abreast of technological advancements in cutting tools and safety protocols enhances the work quality. Participating in courses or certification programs specifically tailored to composite materials can further solidify one’s standing as an authority in this field. Trustworthiness in cutting FRP grating can be conveyed through customer-focused communications. Providing clients or stakeholders with comprehensive explanations of the chosen cutting techniques and safety measures not only builds trust but also establishes clear expectations. It’s possible to bolster this trust by sharing testimonials and success stories from previous projects, reassuring potential customers of your expertise and commitment to quality. In conclusion, cutting FRP grating transcends basic craftsmanship. It combines understanding of the material, precise execution, necessary tooling, rigorous safety practices, and continued learning. Those who excel in this realm not only apply their skills to enhance project outcomes but also contribute to elevating industry standards, setting themselves apart as trusted authorities in a niche that demands both proficiency and careful attention to detail.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024