loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 11, 2025 06:49

Back to list

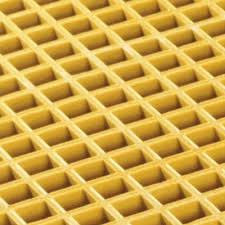

fiberglass reinforced plastic grating

Fiberglass Reinforced Plastic (FRP) grating is an innovative solution known for its versatility and robustness, offering an edge in industries where durability and safety are paramount. As the demand for more efficient and reliable materials grows, understanding the intrinsic benefits and uses of FRP grating becomes essential for professionals looking to integrate this material into their projects.

Expertise in the production of FRP grating ensures that this product is engineered to the highest standards. The advanced techniques used in manufacturing FRP grating, such as pultrusion and molding processes, guarantee consistency and high-quality performance. These processes produce grating with excellent strength-to-weight ratio, allowing it to withstand substantial loads while maintaining structural integrity. For industries where hygienic conditions are non-negotiable, such as food and pharmaceuticals, FRP grating provides an added benefit of easy cleaning and bacteria-resistance. It does not absorb moisture and can be quickly cleaned with standard agents, ensuring compliance with stringent sanitation standards. Authoritative voices in the industry have endorsed FRP grating due to its environmental advantages as well. The production process for FRP products generates a smaller carbon footprint compared to traditional materials. FRP grating is also recyclable, aligning with global sustainability goals and reducing environmental impact. Trustworthiness in the supply and delivery of FRP grating is ensured by working with reputable manufacturers known for their adherence to international quality standards. Certifications from recognized bodies provide reassurance of the FRP grating’s performance, ensuring that stakeholders can rely on its quality and durability. Choosing FRP grating means investing in a material that embodies modern engineering solutions without compromising on safety, efficiency, or sustainability. Adopting FRP grating in your projects elevates not only the structural integrity but also aligns with a commitment to leveraging advanced materials that meet the highest industry standards.

Expertise in the production of FRP grating ensures that this product is engineered to the highest standards. The advanced techniques used in manufacturing FRP grating, such as pultrusion and molding processes, guarantee consistency and high-quality performance. These processes produce grating with excellent strength-to-weight ratio, allowing it to withstand substantial loads while maintaining structural integrity. For industries where hygienic conditions are non-negotiable, such as food and pharmaceuticals, FRP grating provides an added benefit of easy cleaning and bacteria-resistance. It does not absorb moisture and can be quickly cleaned with standard agents, ensuring compliance with stringent sanitation standards. Authoritative voices in the industry have endorsed FRP grating due to its environmental advantages as well. The production process for FRP products generates a smaller carbon footprint compared to traditional materials. FRP grating is also recyclable, aligning with global sustainability goals and reducing environmental impact. Trustworthiness in the supply and delivery of FRP grating is ensured by working with reputable manufacturers known for their adherence to international quality standards. Certifications from recognized bodies provide reassurance of the FRP grating’s performance, ensuring that stakeholders can rely on its quality and durability. Choosing FRP grating means investing in a material that embodies modern engineering solutions without compromising on safety, efficiency, or sustainability. Adopting FRP grating in your projects elevates not only the structural integrity but also aligns with a commitment to leveraging advanced materials that meet the highest industry standards.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

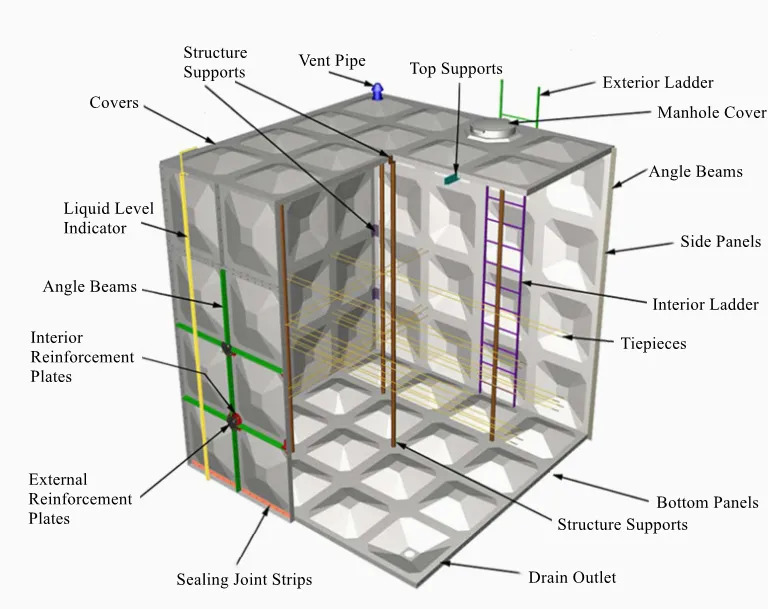

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024