loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 03, 2025 01:53

Back to list

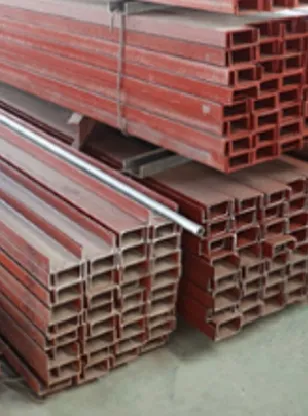

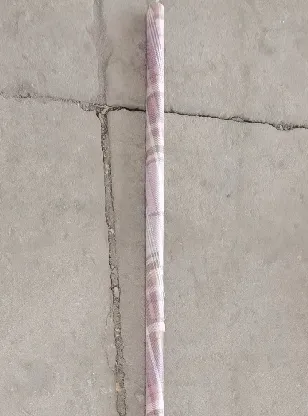

fiberglass rod manufacturers

Navigating the world of fiberglass rod manufacturing can be daunting without the right information and resources. This versatile material has become a staple across industries such as construction, telecommunications, leisure, and agriculture. It is vital for any potential buyer or industry professional to understand the dynamics and intricacies involved in this market to make informed decisions and opt for the best manufacturers. Here's an in-depth guide based on years of industry experience and expertise.

Trustworthiness is the cornerstone of any successful business relationship, especially in manufacturing. Reliable manufacturers maintain transparency in their operations, pricing, and communications. They offer warranties and support services that give clients peace of mind and foster strong, lasting partnerships. Client testimonials and case studies on manufacturers’ websites can provide insights into their ability to deliver as promised and handle any challenges that arise. Moreover, sustainability has become a pressing concern in the industry. Today’s leading fiberglass rod manufacturers are committed to eco-friendly practices, limiting waste, conserving energy, and using sustainable materials wherever possible. Their processes are designed to reduce environmental impact, aligning with global sustainability goals and offering clients an ethically responsible choice. To identify a suitable fiberglass rod manufacturer, engage in thorough research. Evaluate multiple companies, inspect their credentials, and compare their offerings. Reach out to their existing clients to gather unbiased feedback about their experiences. This approach ensures access to the best possible options available, leading to successful project outcomes. In conclusion, the world of fiberglass rod manufacturing is as complex as it is rewarding. Armed with this expertise, industry professionals can confidently navigate this landscape, ensuring they partner with manufacturers who uphold the highest standards of experience, expertise, authoritativeness, and trustworthiness. By doing so, they not only optimize the utility and efficiency of their products but also contribute to a robust and sustainable future in material manufacturing.

Trustworthiness is the cornerstone of any successful business relationship, especially in manufacturing. Reliable manufacturers maintain transparency in their operations, pricing, and communications. They offer warranties and support services that give clients peace of mind and foster strong, lasting partnerships. Client testimonials and case studies on manufacturers’ websites can provide insights into their ability to deliver as promised and handle any challenges that arise. Moreover, sustainability has become a pressing concern in the industry. Today’s leading fiberglass rod manufacturers are committed to eco-friendly practices, limiting waste, conserving energy, and using sustainable materials wherever possible. Their processes are designed to reduce environmental impact, aligning with global sustainability goals and offering clients an ethically responsible choice. To identify a suitable fiberglass rod manufacturer, engage in thorough research. Evaluate multiple companies, inspect their credentials, and compare their offerings. Reach out to their existing clients to gather unbiased feedback about their experiences. This approach ensures access to the best possible options available, leading to successful project outcomes. In conclusion, the world of fiberglass rod manufacturing is as complex as it is rewarding. Armed with this expertise, industry professionals can confidently navigate this landscape, ensuring they partner with manufacturers who uphold the highest standards of experience, expertise, authoritativeness, and trustworthiness. By doing so, they not only optimize the utility and efficiency of their products but also contribute to a robust and sustainable future in material manufacturing.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024