loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 11, 2025 02:34

Back to list

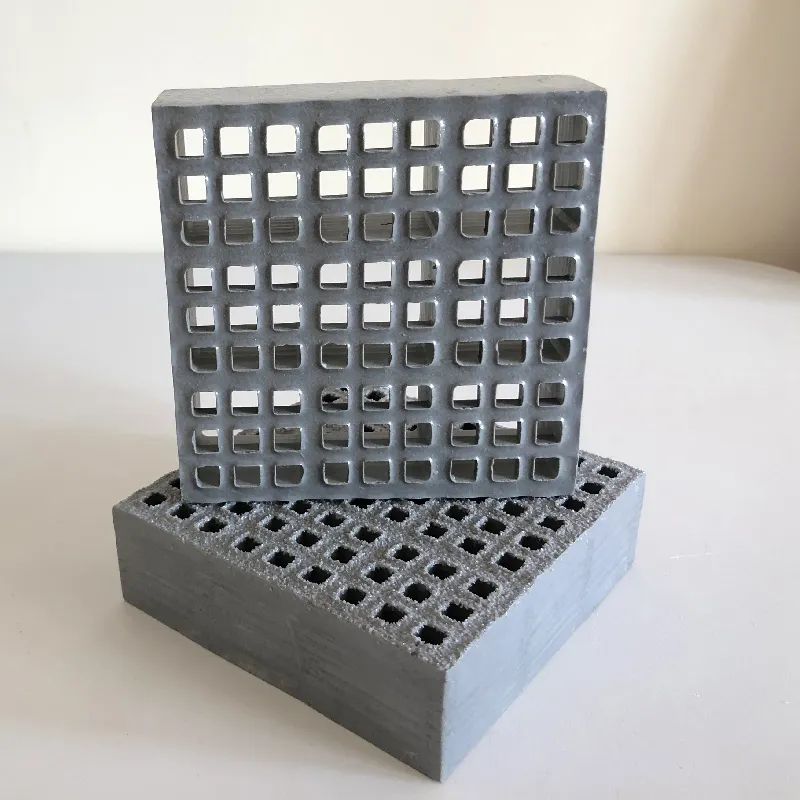

frp micro mesh grating

Fibreglass grating has steadily risen in popularity over the past decade, establishing itself as a superior alternative to traditional materials like steel and aluminum. This renewable composite material has not only carved a niche in various industrial applications but also impressed those looking for durability combined with cost-effectiveness. With an extensive array of uses, fibreglass grating offers unmatched practicality and performance, driven by an increasing need for corrosion-resistant and long-lasting solutions.

However, the advantages of fibreglass grating are best evaluated by considering real-life applications and case studies, which speak volumes about its efficacy. In the case of a coastal oil refinery, the switch to fibreglass grating reduced replacement schedules by over 30%, factoring in cost savings linked to material longevity and fewer safety incidents. Furthermore, experts from a leading cruise ship company reported a 40% reduction in maintenance costs after replacing steel grating with fibreglass alternatives on their decks. Despite these advantages, it's important to acknowledge areas where fibreglass might not be the perfect fit. While it performs extraordinarily well under a wide range of conditions and exceeds expectations in corrosive environments, for applications requiring extreme heat resistance, other materials might be more suitable due to the material's thermal limitations. As businesses increasingly prioritize sustainability, fibreglass grating presents a green alternative, significantly contributing to reduced environmental impact. Fibreglass manufacturing consumes less energy than metals, and the longevity of the product decreases material turnover, making it an environmentally responsible choice. In conclusion, fibreglass grating stands as a beacon of innovation in materials technology, offering a blend of resilience, versatility, and economic efficiency. For industries looking to optimize their operations while ensuring safety and compliance, fibreglass grating is not just a component but a comprehensive solution. With the backing of expert testimonials and proven case studies, it confidently meets demanding applications, thus cementing its place as a fundamental material choice for the forward-thinking industry. By understanding the needs of the environment it serves, businesses can effectively leverage fibreglass grating, ensuring they stay ahead not only in terms of operational efficiency but also in minimizing risks and contributing to a sustainable future.

However, the advantages of fibreglass grating are best evaluated by considering real-life applications and case studies, which speak volumes about its efficacy. In the case of a coastal oil refinery, the switch to fibreglass grating reduced replacement schedules by over 30%, factoring in cost savings linked to material longevity and fewer safety incidents. Furthermore, experts from a leading cruise ship company reported a 40% reduction in maintenance costs after replacing steel grating with fibreglass alternatives on their decks. Despite these advantages, it's important to acknowledge areas where fibreglass might not be the perfect fit. While it performs extraordinarily well under a wide range of conditions and exceeds expectations in corrosive environments, for applications requiring extreme heat resistance, other materials might be more suitable due to the material's thermal limitations. As businesses increasingly prioritize sustainability, fibreglass grating presents a green alternative, significantly contributing to reduced environmental impact. Fibreglass manufacturing consumes less energy than metals, and the longevity of the product decreases material turnover, making it an environmentally responsible choice. In conclusion, fibreglass grating stands as a beacon of innovation in materials technology, offering a blend of resilience, versatility, and economic efficiency. For industries looking to optimize their operations while ensuring safety and compliance, fibreglass grating is not just a component but a comprehensive solution. With the backing of expert testimonials and proven case studies, it confidently meets demanding applications, thus cementing its place as a fundamental material choice for the forward-thinking industry. By understanding the needs of the environment it serves, businesses can effectively leverage fibreglass grating, ensuring they stay ahead not only in terms of operational efficiency but also in minimizing risks and contributing to a sustainable future.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024