loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 12, 2025 18:08

Back to list

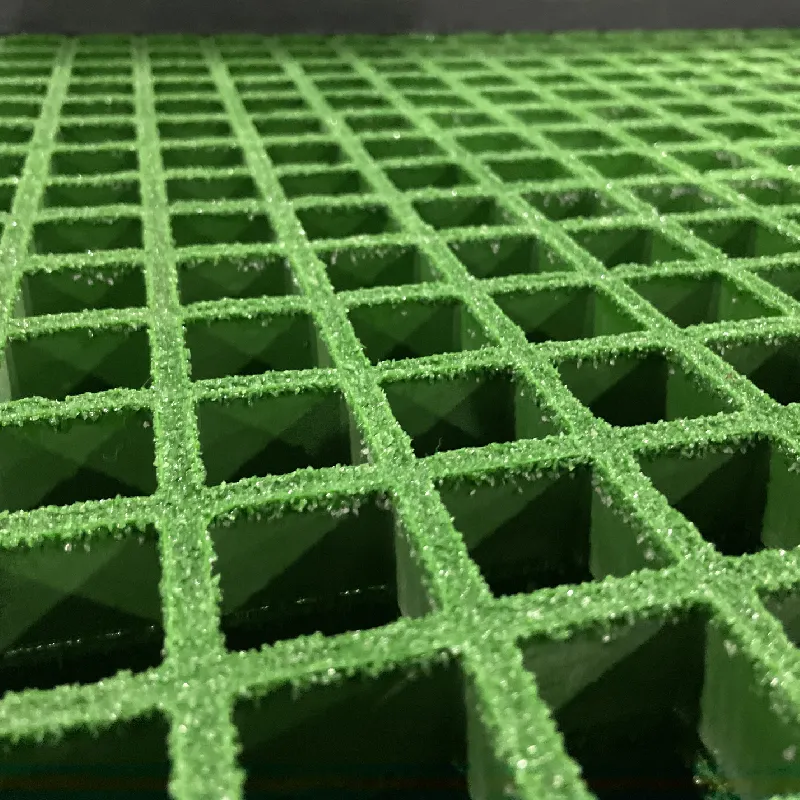

floor drain grating

Floor drain gratings serve as crucial components in residential, industrial, and commercial environments. These unobtrusive elements perform vital functions, but their significance is often overlooked until issues arise. A deep understanding of this product, from experience and expertise to authoritativeness and trustworthiness, ensures informed decisions and enhances user satisfaction.

Authoritativeness in the choice and use of floor drain gratings often derives from adherence to national or international standards. Products that meet these standards have undergone rigorous testing to confirm performance under specific conditions. Industry standards, such as those from the American Society for Testing and Materials (ASTM), provide benchmarks for material quality, strength, and corrosion resistance. Choosing gratings that comply with such standards guarantees a level of durability and safety recognized by experts. Trustworthiness of the grating installations can be further assured by consulting qualified professionals for installation and maintenance. Regular inspections can catch any potential issues before they become major problems. Maintenance includes routine cleaning to prevent build-up of debris and checking for any signs of wear or corrosion that could compromise function. Lastly, an understanding of environmental factors is crucial for the life span and performance of floor drain gratings. In outdoor settings, gratings are exposed to varying weather conditions which may influence material choice. Coastal areas, for example, demand materials resistant to salt-induced corrosion, while industrial areas might require gratings that can withstand chemical exposures. In summary, the selection and maintenance of floor drain gratings should be guided by comprehensive knowledge and expertise. Emphasizing experience, attention to standards, and preventive maintenance not only ensures the durability and reliability of the drainage system but also enhances safety and efficiency in both residential and commercial applications. As such, floor drain gratings are far more than simple fixtures—they are investments in the infrastructure of cleanliness, safety, and operational success.

Authoritativeness in the choice and use of floor drain gratings often derives from adherence to national or international standards. Products that meet these standards have undergone rigorous testing to confirm performance under specific conditions. Industry standards, such as those from the American Society for Testing and Materials (ASTM), provide benchmarks for material quality, strength, and corrosion resistance. Choosing gratings that comply with such standards guarantees a level of durability and safety recognized by experts. Trustworthiness of the grating installations can be further assured by consulting qualified professionals for installation and maintenance. Regular inspections can catch any potential issues before they become major problems. Maintenance includes routine cleaning to prevent build-up of debris and checking for any signs of wear or corrosion that could compromise function. Lastly, an understanding of environmental factors is crucial for the life span and performance of floor drain gratings. In outdoor settings, gratings are exposed to varying weather conditions which may influence material choice. Coastal areas, for example, demand materials resistant to salt-induced corrosion, while industrial areas might require gratings that can withstand chemical exposures. In summary, the selection and maintenance of floor drain gratings should be guided by comprehensive knowledge and expertise. Emphasizing experience, attention to standards, and preventive maintenance not only ensures the durability and reliability of the drainage system but also enhances safety and efficiency in both residential and commercial applications. As such, floor drain gratings are far more than simple fixtures—they are investments in the infrastructure of cleanliness, safety, and operational success.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024