loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 17, 2025 15:26

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

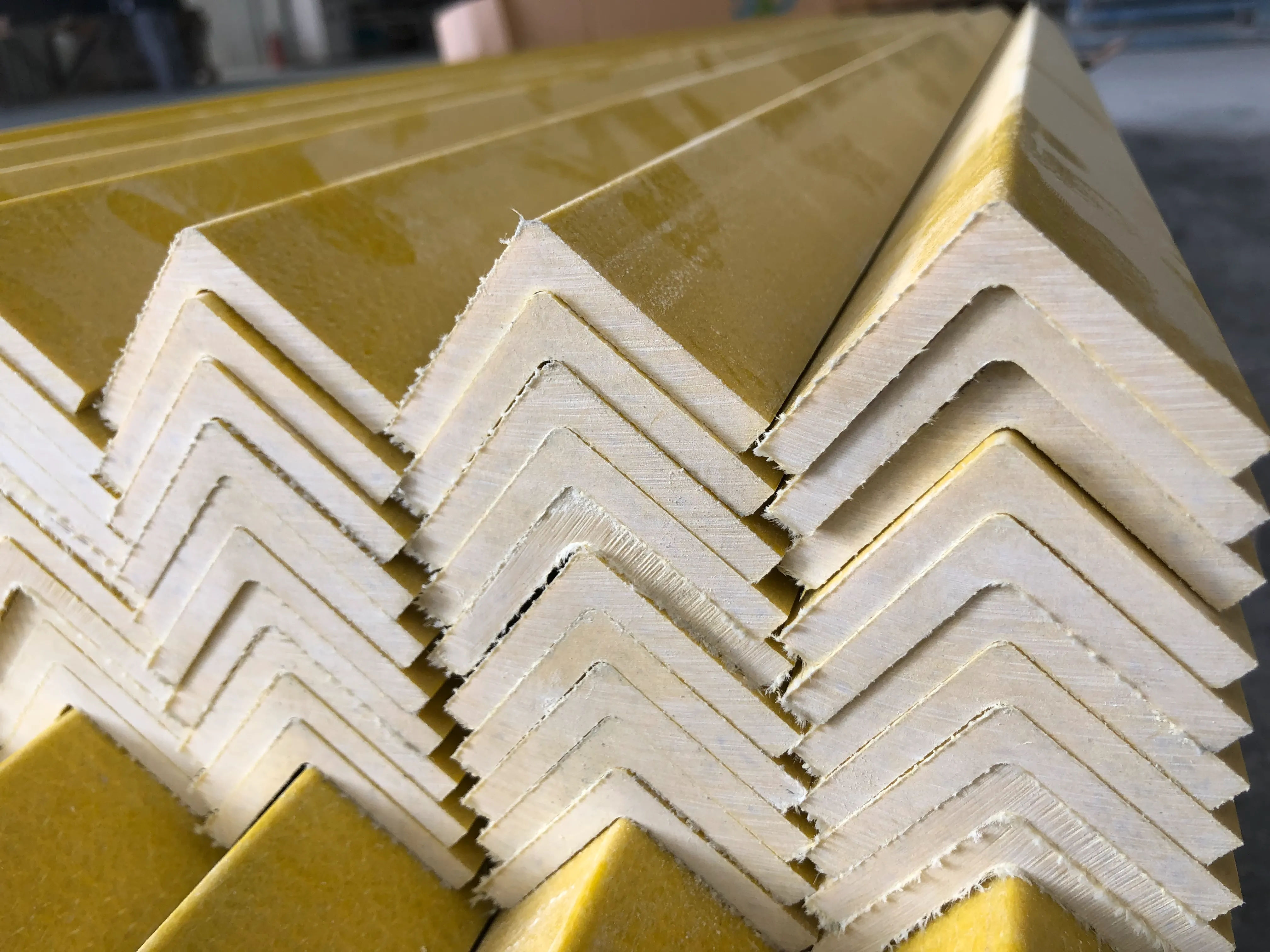

Fiber Reinforced Polymer (FRP) deck panels have immensely transformed the landscape of construction and engineering due to their remarkable properties and wide-ranging applications. As a proficient Google SEO specialist, you realize the necessity of crafting content that not only ranks well but also speaks directly to the needs and concerns of professionals in the field. This article serves as an authoritative guide on FRP deck panels, highlighting their benefits, applications, and a critical assessment of their use in modern construction.

In terms of implementation, professionals have access to various FRP panel configurations, including pultruded, molded, and sandwich panels, each specified for different load-bearing and environmental requirements. Selection of the appropriate type involves a comprehensive assessment of anticipated stress factors, environmental exposure, and long-term maintenance considerations. Expertise in selecting and installing the correct FRP deck panels can result in substantial reductions in lifecycle costs and enhanced structural integrity. To exemplify trustworthiness, consider numerous case studies showcasing successful applications of FRP deck panels. Noteworthy projects such as pedestrian bridges in Europe, which have replaced conventional concrete with FRP due to its rapid installation and minimal maintenance demands, serve as a testament to the material's reliability and efficiency. These instances illustrate not only the panels’ adept handling of heavy foot traffic but also their aesthetic versatility, accommodating both traditional and modern design preferences. Finally, for every construction professional considering FRP deck panels, collaborating with experienced suppliers and engineers is critical to ensuring optimal results. Engaging with certified personnel who possess in-depth technical knowledge and track records in working with FRP materials minimizes potential pitfalls and maximizes project success. In conclusion, FRP deck panels offer an unparalleled blend of durability, lightweight properties, and resistance to adverse conditions, making them a superior option over traditional materials. Their integration into architectural and infrastructural projects continues to be driven by the measurable benefits they provide, underscored by a growing body of authoritative research and successful real-world applications. For those in the industry, embracing the advancements in FRP technology represents not just a trend, but a strategic move towards sustainable and efficient construction practices.

In terms of implementation, professionals have access to various FRP panel configurations, including pultruded, molded, and sandwich panels, each specified for different load-bearing and environmental requirements. Selection of the appropriate type involves a comprehensive assessment of anticipated stress factors, environmental exposure, and long-term maintenance considerations. Expertise in selecting and installing the correct FRP deck panels can result in substantial reductions in lifecycle costs and enhanced structural integrity. To exemplify trustworthiness, consider numerous case studies showcasing successful applications of FRP deck panels. Noteworthy projects such as pedestrian bridges in Europe, which have replaced conventional concrete with FRP due to its rapid installation and minimal maintenance demands, serve as a testament to the material's reliability and efficiency. These instances illustrate not only the panels’ adept handling of heavy foot traffic but also their aesthetic versatility, accommodating both traditional and modern design preferences. Finally, for every construction professional considering FRP deck panels, collaborating with experienced suppliers and engineers is critical to ensuring optimal results. Engaging with certified personnel who possess in-depth technical knowledge and track records in working with FRP materials minimizes potential pitfalls and maximizes project success. In conclusion, FRP deck panels offer an unparalleled blend of durability, lightweight properties, and resistance to adverse conditions, making them a superior option over traditional materials. Their integration into architectural and infrastructural projects continues to be driven by the measurable benefits they provide, underscored by a growing body of authoritative research and successful real-world applications. For those in the industry, embracing the advancements in FRP technology represents not just a trend, but a strategic move towards sustainable and efficient construction practices.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024