loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 02, 2025 04:29

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

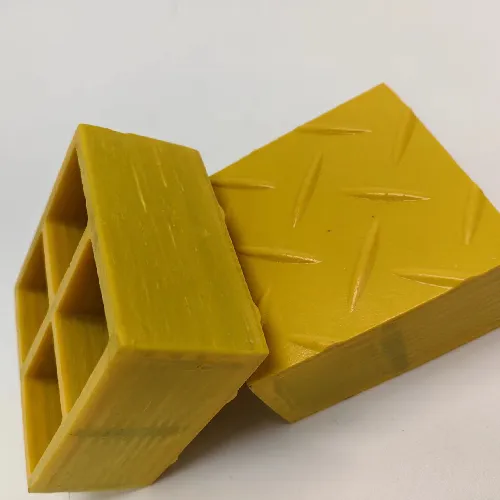

FRP drain channels have rapidly become an essential component in various industrial, commercial, and residential projects due to their durability, lightweight nature, and resistance to corrosion. As these channels gain popularity, it's essential to understand why they are considered not just a viable option but often the best choice for efficient drainage systems.

From an engineering perspective, the customizable nature of FRP drain channels is particularly appealing. Manufacturers can tailor these products to meet specific project requirements, offering a variety of designs, sizes, and features that align with unique drainage needs. Whether it's for heavy-duty applications or environments requiring precise flow control, FRP channels can be engineered to deliver optimal performance. In terms of lifecycle cost, FRP drain channels offer a remarkable return on investment. Although the initial cost may be higher than some traditional materials, the extended lifespan and reduced maintenance needs significantly offset this initial investment. When considering the total cost of ownership, including installation, maintenance, and potential replacements, FRP proves to be a cost-effective choice. Environmental considerations also play a vital role in the increasing adoption of FRP drain channels. As industries and construction projects move towards sustainable practices, the eco-friendly production process and recyclable nature of FRP make it a preferred option. Unlike materials that deplete natural resources or contribute significantly to pollution, FRP can be recycled, reducing the overall environmental footprint of a project. In conclusion, FRP drain channels are not just a modern alternative but a superior solution for efficient and sustainable drainage. Their combination of durability, corrosion resistance, ease of installation, and environmental benefits makes them a wise investment across numerous applications. As industries continue to evolve and prioritize efficiency and sustainability, the shift towards FRP drain channels is likely to accelerate, driven by their proven benefits and the growing demand for advanced infrastructure solutions. Choosing FRP means investing in a future-ready drainage system that stands the test of time and meets the highest standards of performance and environmental responsibility.

From an engineering perspective, the customizable nature of FRP drain channels is particularly appealing. Manufacturers can tailor these products to meet specific project requirements, offering a variety of designs, sizes, and features that align with unique drainage needs. Whether it's for heavy-duty applications or environments requiring precise flow control, FRP channels can be engineered to deliver optimal performance. In terms of lifecycle cost, FRP drain channels offer a remarkable return on investment. Although the initial cost may be higher than some traditional materials, the extended lifespan and reduced maintenance needs significantly offset this initial investment. When considering the total cost of ownership, including installation, maintenance, and potential replacements, FRP proves to be a cost-effective choice. Environmental considerations also play a vital role in the increasing adoption of FRP drain channels. As industries and construction projects move towards sustainable practices, the eco-friendly production process and recyclable nature of FRP make it a preferred option. Unlike materials that deplete natural resources or contribute significantly to pollution, FRP can be recycled, reducing the overall environmental footprint of a project. In conclusion, FRP drain channels are not just a modern alternative but a superior solution for efficient and sustainable drainage. Their combination of durability, corrosion resistance, ease of installation, and environmental benefits makes them a wise investment across numerous applications. As industries continue to evolve and prioritize efficiency and sustainability, the shift towards FRP drain channels is likely to accelerate, driven by their proven benefits and the growing demand for advanced infrastructure solutions. Choosing FRP means investing in a future-ready drainage system that stands the test of time and meets the highest standards of performance and environmental responsibility.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024