loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 24, 2025 00:55

Back to list

frp filter vessel

Fiberglass Reinforced Plastic (FRP) filter vessels have emerged as a cutting-edge solution in various industrial and commercial filtration applications. The demand for efficient, corrosion-resistant, and lightweight materials has propelled FRP to the forefront, making it a preferred choice across sectors such as water treatment, chemical processing, and food and beverage industries.

Authoritativeness in the field of FRP technology is underscored by extensive research and innovation. The development of advanced resins and composite reinforcements has substantially improved the structural integrity and chemical resistance of FRP vessels. Cutting-edge manufacturing processes, such as filament winding and vacuum infusion, have enhanced the capability to produce complex shapes and large-diameter vessels without compromising strength. These technological advancements reflect the authority of FRP as an evolved material solution in filtration systems. Trustworthiness is paramount in industries that rely on filtration systems for critical operations. FRP filter vessels are subjected to rigorous testing and quality assurance protocols to ensure they meet industry standards such as ASME, ASTM, and ISO. Third-party certifications and regular inspections further attest to their reliability, giving end-users confidence in their performance. Additionally, many manufacturers offer comprehensive warranties and post-sale support, reinforcing the trust positioned in their products. In an era where sustainability is crucial, FRP filter vessels also present an environmentally friendly solution. The longevity and low maintenance requirements of these vessels result in less frequent replacement and reduced waste. Furthermore, advancements in recycling processes for FRP materials are being developed, contributing to a more sustainable lifecycle for filtration systems. In conclusion, FRP filter vessels exemplify a modern approach to addressing the challenges associated with industrial filtration. Their combination of durability, adaptability, and economic efficiency makes them an ideal choice for businesses looking to enhance their filtration systems. As industries continue to prioritize reliability and cost-effectiveness, the utilization of FRP filter vessels is poised to expand, underscoring their status as a crucial component in sustainable and efficient industrial operations.

Authoritativeness in the field of FRP technology is underscored by extensive research and innovation. The development of advanced resins and composite reinforcements has substantially improved the structural integrity and chemical resistance of FRP vessels. Cutting-edge manufacturing processes, such as filament winding and vacuum infusion, have enhanced the capability to produce complex shapes and large-diameter vessels without compromising strength. These technological advancements reflect the authority of FRP as an evolved material solution in filtration systems. Trustworthiness is paramount in industries that rely on filtration systems for critical operations. FRP filter vessels are subjected to rigorous testing and quality assurance protocols to ensure they meet industry standards such as ASME, ASTM, and ISO. Third-party certifications and regular inspections further attest to their reliability, giving end-users confidence in their performance. Additionally, many manufacturers offer comprehensive warranties and post-sale support, reinforcing the trust positioned in their products. In an era where sustainability is crucial, FRP filter vessels also present an environmentally friendly solution. The longevity and low maintenance requirements of these vessels result in less frequent replacement and reduced waste. Furthermore, advancements in recycling processes for FRP materials are being developed, contributing to a more sustainable lifecycle for filtration systems. In conclusion, FRP filter vessels exemplify a modern approach to addressing the challenges associated with industrial filtration. Their combination of durability, adaptability, and economic efficiency makes them an ideal choice for businesses looking to enhance their filtration systems. As industries continue to prioritize reliability and cost-effectiveness, the utilization of FRP filter vessels is poised to expand, underscoring their status as a crucial component in sustainable and efficient industrial operations.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

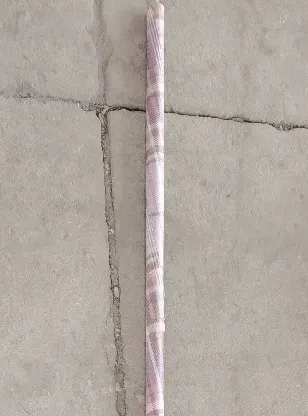

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024