loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 18, 2025 09:58

Back to list

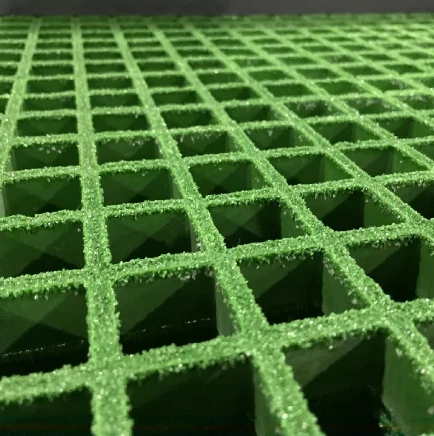

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Fiber Reinforced Plastic (FRP) grating has emerged as a revolutionary solution in multiple industrial applications due to its unique synthesis of advantages over traditional materials like steel and aluminum. FRP grating has captured significant attention from industries ranging from chemical processing plants to marine environments due to its unmatched corrosion resistance, lightweight nature, and exceptional strength-to-weight ratio. In the forthcoming discourse, we delve into the intricate world of FRP grating, elucidating its applications, benefits, and why it stands as the cornerstone for future industrial applications.

Thermal and electrical non-conductivity further expand the applications of FRP grating. In environments where electrical safety is a concern, the non-conductive nature of FRP grating is invaluable. Likewise, its resistance to thermal conductivity makes it a suitable choice for environments with fluctuating temperatures or where heat insulation is required. The customization potential of FRP grating is another aspect where it outshines traditional grating options. It can be manufactured in a variety of colors and patterns, not just for aesthetic appeal, but also for function, such as color-coded safety zones. Additionally, its ability to be molded into intricate shapes and configurations ensures that specific application requirements can be met without compromising structure or performance. Authoritative voices within the industry advocate for FRP grating based on empirical data and applied use cases that reflect its superiority and adaptability. Case studies across sectors consistently document not just cost savings and enhanced operational efficiency, but also a marked improvement in workplace safety metrics. Such endorsements underscore the credibility and reliability of FRP grating as not only a product but as a solution to industry-wide challenges. In conclusion, FRP grating stands as a testament to the advancements in material science, offering customizable, durable, and safe solutions for a multitude of industrial applications. With its ability to withstand harsh environments, reduce costs, and ensure safety, the shift towards embracing FRP grating is not merely advised but imperative for industries striving for excellence and sustainability.

Thermal and electrical non-conductivity further expand the applications of FRP grating. In environments where electrical safety is a concern, the non-conductive nature of FRP grating is invaluable. Likewise, its resistance to thermal conductivity makes it a suitable choice for environments with fluctuating temperatures or where heat insulation is required. The customization potential of FRP grating is another aspect where it outshines traditional grating options. It can be manufactured in a variety of colors and patterns, not just for aesthetic appeal, but also for function, such as color-coded safety zones. Additionally, its ability to be molded into intricate shapes and configurations ensures that specific application requirements can be met without compromising structure or performance. Authoritative voices within the industry advocate for FRP grating based on empirical data and applied use cases that reflect its superiority and adaptability. Case studies across sectors consistently document not just cost savings and enhanced operational efficiency, but also a marked improvement in workplace safety metrics. Such endorsements underscore the credibility and reliability of FRP grating as not only a product but as a solution to industry-wide challenges. In conclusion, FRP grating stands as a testament to the advancements in material science, offering customizable, durable, and safe solutions for a multitude of industrial applications. With its ability to withstand harsh environments, reduce costs, and ensure safety, the shift towards embracing FRP grating is not merely advised but imperative for industries striving for excellence and sustainability.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024