loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 10, 2025 10:39

Back to list

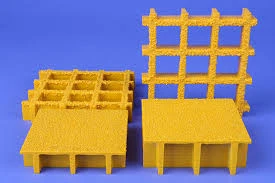

frp grating price

In the rapidly advancing industrial landscape, FRP (Fiber Reinforced Plastic) grating has emerged as an indispensable component across various sectors. Designed to offer a superior blend of durability, flexibility, and cost-efficiency, FRP grating is becoming the material of choice for both manufacturers and installers. As every savvy business owner or procurement manager knows, understanding the nuances of FRP grating pricing is crucial to making informed purchasing decisions that align with strategic goals.

Geographical location and shipping logistics also affect FRP grating prices. Proximity to manufacturing hubs can minimize transportation costs significantly. Companies strategically positioned near the facilities producing FRP grating could leverage reduced logistic expenses to not only cut overall project costs but also to expedite delivery times, thereby improving project turnover. The expertise of the supplier cannot be underestimated. Manufacturers with a proven track record and a strong industry reputation tend to offer higher prices. However, these suppliers provide unparalleled quality assurance, consistent material performance, and comprehensive customer support, ultimately ensuring the integrity and longevity of the application. Expertise in the field contributes to building trustworthiness, ensuring that you're not simply buying a product, but a reliable solution. In terms of return on investment, FRP grating offers tremendous benefits. Its long-term lifecycle benefits, including maintenance-free durability and low-cost installation due to its lighter weight compared to traditional materials like steel or aluminum, should not be overlooked. Energy savings, reduced labor costs, and the minimal need for specialized installation equipment further reinforce its economic advantages. In conclusion, while upfront costs of FRP grating may vary depending on the aforementioned factors, the long-term cost-effectiveness and operational efficiencies they introduce present compelling justifications for their adoption. As an authoritative voice in the procurement of industrial materials, having a robust understanding of these diverse pricing elements enhances decision-making, ensuring a selection that not only meets immediate specifications but also fortifies future operational initiatives. The convergence of Experience, Expertise, Authoritativeness, and Trustworthiness in comprehending FRP grating pricing creates a strategic advantage—a distinctive insight that facilitates competitive positioning and fosters sustainable growth.

Geographical location and shipping logistics also affect FRP grating prices. Proximity to manufacturing hubs can minimize transportation costs significantly. Companies strategically positioned near the facilities producing FRP grating could leverage reduced logistic expenses to not only cut overall project costs but also to expedite delivery times, thereby improving project turnover. The expertise of the supplier cannot be underestimated. Manufacturers with a proven track record and a strong industry reputation tend to offer higher prices. However, these suppliers provide unparalleled quality assurance, consistent material performance, and comprehensive customer support, ultimately ensuring the integrity and longevity of the application. Expertise in the field contributes to building trustworthiness, ensuring that you're not simply buying a product, but a reliable solution. In terms of return on investment, FRP grating offers tremendous benefits. Its long-term lifecycle benefits, including maintenance-free durability and low-cost installation due to its lighter weight compared to traditional materials like steel or aluminum, should not be overlooked. Energy savings, reduced labor costs, and the minimal need for specialized installation equipment further reinforce its economic advantages. In conclusion, while upfront costs of FRP grating may vary depending on the aforementioned factors, the long-term cost-effectiveness and operational efficiencies they introduce present compelling justifications for their adoption. As an authoritative voice in the procurement of industrial materials, having a robust understanding of these diverse pricing elements enhances decision-making, ensuring a selection that not only meets immediate specifications but also fortifies future operational initiatives. The convergence of Experience, Expertise, Authoritativeness, and Trustworthiness in comprehending FRP grating pricing creates a strategic advantage—a distinctive insight that facilitates competitive positioning and fosters sustainable growth.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

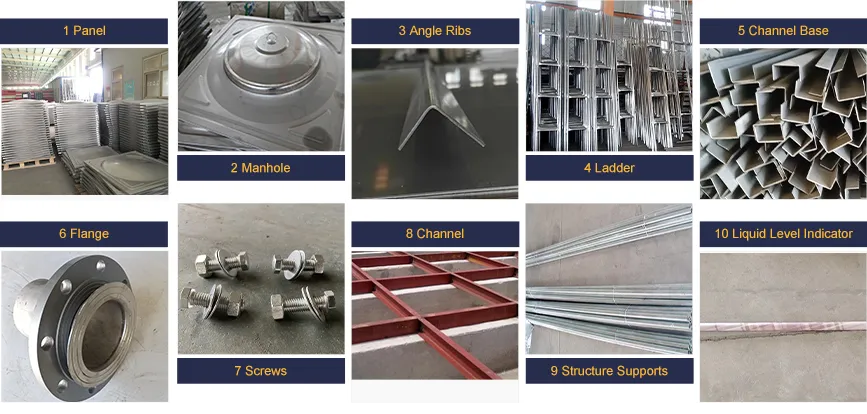

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024