loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 13, 2025 10:11

Back to list

frp pressure vessels

In the realm of modern industrial applications, FRP (Fiberglass Reinforced Plastic) pressure vessels stand out as a pivotal advancement, offering unparalleled durability and efficiency across a multitude of sectors. These pressure vessels are fabricated with a matrix of polymer reinforced with glass fibers, forging a composite material that excels in corrosive environments and presents a viable alternative to traditional metal vessels.

In terms of expertise, manufacturers of FRP pressure vessels continue to push the boundaries of composite material science. Ongoing research and development are focused on enhancing the material properties, such as impact resistance and thermal stability. The integration of nano-materials and advanced resins further augments the performance characteristics, paving the way for future innovations and expanding the operational envelope of these vessels. The authoritative stance of FRP vessel manufacturers is grounded in decades of experience and a robust adherence to standards. These producers collaborate with end-users to conduct on-site evaluations and post-installation inspections, ensuring a seamless integration into established systems and confirming operational efficacy. Such partnerships are integral to tailoring solutions that align with specific client requirements and regulatory landscapes. Trust in FRP pressure vessels is built not only on their proven performance but also on the reliability of service networks that include regular maintenance checks, training modules for handling, and feedback loops to incorporate user experiences into ongoing product improvements. This comprehensive approach underscores a commitment to maintaining the integrity and high standards of FRP vessels in various industrial applications. In conclusion, FRP pressure vessels offer an advanced solution for industries demanding durable, resistant, and customizable containers capable of operating under challenging conditions. Their widespread adoption speaks volumes about their efficacy and the trust positioned in composite materials as the future of industrial pressure vessel applications. As technology evolves, so too will the capabilities of FRP vessels, continuing their legacy as indispensable assets in the industrial toolkit.

In terms of expertise, manufacturers of FRP pressure vessels continue to push the boundaries of composite material science. Ongoing research and development are focused on enhancing the material properties, such as impact resistance and thermal stability. The integration of nano-materials and advanced resins further augments the performance characteristics, paving the way for future innovations and expanding the operational envelope of these vessels. The authoritative stance of FRP vessel manufacturers is grounded in decades of experience and a robust adherence to standards. These producers collaborate with end-users to conduct on-site evaluations and post-installation inspections, ensuring a seamless integration into established systems and confirming operational efficacy. Such partnerships are integral to tailoring solutions that align with specific client requirements and regulatory landscapes. Trust in FRP pressure vessels is built not only on their proven performance but also on the reliability of service networks that include regular maintenance checks, training modules for handling, and feedback loops to incorporate user experiences into ongoing product improvements. This comprehensive approach underscores a commitment to maintaining the integrity and high standards of FRP vessels in various industrial applications. In conclusion, FRP pressure vessels offer an advanced solution for industries demanding durable, resistant, and customizable containers capable of operating under challenging conditions. Their widespread adoption speaks volumes about their efficacy and the trust positioned in composite materials as the future of industrial pressure vessel applications. As technology evolves, so too will the capabilities of FRP vessels, continuing their legacy as indispensable assets in the industrial toolkit.

Share

Next:

Latest news

-

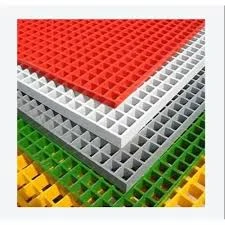

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024