loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp rectangular tube

The Advantages and Applications of FRP Rectangular Tubes

Fiber Reinforced Polymer (FRP) rectangular tubes are becoming increasingly popular in various industries due to their exceptional properties and versatility. Constructed from a polymer matrix reinforced with fiber materials, typically glass fiber or carbon fiber, these tubes offer a unique combination of strength, lightweight, corrosion resistance, and design flexibility. In this article, we will explore the advantages of FRP rectangular tubes and their applications across different sectors.

1. Strength-to-Weight Ratio

One of the most significant advantages of FRP rectangular tubes is their impressive strength-to-weight ratio. Compared to traditional materials such as steel or aluminum, FRP offers similar or even superior strength while being significantly lighter. This characteristic makes FRP rectangular tubes an ideal choice for applications where weight-saving is crucial, such as in the aerospace and automotive industries. The reduced weight leads to enhanced fuel efficiency and lower operational costs.

2. Corrosion Resistance

FRP materials exhibit excellent resistance to various corrosive environments, which makes them highly suitable for applications in industries such as chemical processing, marine, and construction. Unlike metal options, FRP rectangular tubes do not rust, corrode, or degrade when exposed to harmful chemicals or seawater. This durability reduces the need for maintenance and replacement, leading to lower long-term costs and improved longevity of structures and products.

3. Design Flexibility

Another remarkable feature of FRP rectangular tubes is their design flexibility. Manufacturers can tailor the properties of FRP materials according to the specific requirements of various applications. By adjusting the type and orientation of the fibers, as well as the type of resin used, engineers can create tubes with varying levels of strength, stiffness, and other mechanical properties. This adaptability makes FRP rectangular tubes suitable for a variety of specialized applications, from custom structural components to innovative architectural designs.

4. Thermal and Electrical Insulation

In addition to their mechanical benefits, FRP rectangular tubes also provide excellent thermal and electrical insulation. This attribute is particularly advantageous in the electrical and electronics industries, where non-conductive materials are required to prevent short circuits and overheating. Furthermore, in applications exposed to extreme temperatures, FRP can maintain its structural integrity, ensuring safety and performance.

frp rectangular tube

5

. Environmental ConsiderationsAs the world increasingly focuses on sustainable practices, FRP materials stand out due to their potential for recycling and reuse. Additionally, the lightweight nature of FRP contributes to reduced energy consumption during transportation and installation. Companies involved in green building practices frequently utilize FRP rectangular tubes to enhance the sustainability of their projects.

Applications of FRP Rectangular Tubes

FRP rectangular tubes are widely used across various sectors

- Construction and Civil Engineering FRP tubes are employed in infrastructure projects, including bridges, railings, and structural supports, due to their lightweight and strength. Their corrosion resistance is particularly beneficial in harsh environments, such as marine applications.

- Aerospace and Automotive In the aerospace and automotive industries, the need for lightweight yet strong structural components is paramount. FRP rectangular tubes are often used in aircraft interiors and automotive chassis parts.

- Chemical Processing Given their excellent chemical resistance, FRP rectangular tubes are ideal for piping systems, tanks, and other components in the chemical industry.

- Sports Equipment The sports sector also embraces FRP technology, as these materials provide the necessary strength without adding excessive weight, making them ideal for manufacturing lightweight but durable sporting goods.

Conclusion

In conclusion, FRP rectangular tubes represent a significant advancement in material technology, offering a range of benefits that traditional materials cannot match. With their superior strength-to-weight ratio, corrosion resistance, design flexibility, and environmental advantages, these tubes are carving out a prominent niche in various industries. As technology continues to evolve, we can expect to see even more innovative applications for FRP rectangular tubes, further enhancing their importance in modern engineering and construction.

-

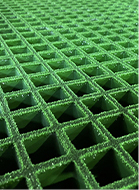

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024