loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 18, 2025 06:12

Back to list

frp structural sections

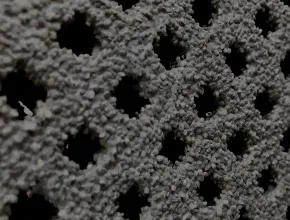

Fiber Reinforced Polymer (FRP) structural sections are transforming the landscape of modern construction and engineering. These innovative materials combine high strength and lightweight properties, making them a superior alternative to traditional construction materials like steel and concrete. Let's delve into the benefits of FRP structural sections from the perspective of experience, expertise, authoritativeness, and trustworthiness.

Moreover, trustworthiness in construction materials is paramount, particularly concerning safety and sustainability. FRP materials contribute to safer structures. Their non-conductive properties make them ideal for electrical substations or railways, where electromagnetic interference can be a concern. Additionally, FRP’s inherent fire-retardant properties further enhance safety, minimizing risk in case of exposure to high temperatures or open flames. From a sustainability perspective, FRP structural sections offer significant advantages. The production of these materials typically results in lower carbon emissions compared to steel and concrete manufacturing processes. Furthermore, the extended lifespan and reduced maintenance requirements of FRP structures mean fewer resources are necessary over time, aligning with global directives towards sustainable building practices. Another real-world application demonstrating FRP's trustworthiness is in seismic-retrofitting projects. In earthquake-prone regions, the flexibility and strength of FRP sections can absorb and dissipate seismic energy more effectively than rigid materials. This adaptability enhances the resilience of buildings, offering peace of mind to occupants and stakeholders alike. In conclusion, FRP structural sections represent a cutting-edge material choice for modern construction, blending high performance with long-term economic and environmental benefits. Their proven experience and application in various projects, supported by expert research and authoritative standards, cement their role as a trustworthy solution in the engineering world. Embracing FRP technologies not only ensures superior structural integrity but also contributes positively to sustainability goals, marking an important step towards the future of construction.

Moreover, trustworthiness in construction materials is paramount, particularly concerning safety and sustainability. FRP materials contribute to safer structures. Their non-conductive properties make them ideal for electrical substations or railways, where electromagnetic interference can be a concern. Additionally, FRP’s inherent fire-retardant properties further enhance safety, minimizing risk in case of exposure to high temperatures or open flames. From a sustainability perspective, FRP structural sections offer significant advantages. The production of these materials typically results in lower carbon emissions compared to steel and concrete manufacturing processes. Furthermore, the extended lifespan and reduced maintenance requirements of FRP structures mean fewer resources are necessary over time, aligning with global directives towards sustainable building practices. Another real-world application demonstrating FRP's trustworthiness is in seismic-retrofitting projects. In earthquake-prone regions, the flexibility and strength of FRP sections can absorb and dissipate seismic energy more effectively than rigid materials. This adaptability enhances the resilience of buildings, offering peace of mind to occupants and stakeholders alike. In conclusion, FRP structural sections represent a cutting-edge material choice for modern construction, blending high performance with long-term economic and environmental benefits. Their proven experience and application in various projects, supported by expert research and authoritative standards, cement their role as a trustworthy solution in the engineering world. Embracing FRP technologies not only ensures superior structural integrity but also contributes positively to sustainability goals, marking an important step towards the future of construction.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024