loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 15, 2025 03:06

Back to list

frp vessel for water treatment

Choosing the right materials and designs for storage solutions is crucial for industries dealing with chemicals, water, and other liquids. FRP (Fiberglass Reinforced Plastic) tanks and vessels stand out as exceptional options due to their durability, corrosion resistance, and versatility. Drawing from years of professional experience and industry expertise, this article delves into why FRP tanks and vessels are unparalleled in the market.

Further establishing FRP's authoritative stance in the product market is its environmentally friendly nature. Sustainability is becoming a critical concern across industries, and FRP tanks and vessels address this need with their energy-efficient production processes and long-term usability. They contribute to a reduced carbon footprint, aligning with global environmental goals while maintaining top-notch industrial standards—a factor that resonates well with environmentally-conscious businesses today. Trustworthiness in FRP tanks and vessels is cemented by rigorous testing and certifications. Every product undergoes stringent quality assessments, from leak tests to pressure tests, ensuring they meet safety regulations and perform under expected operational conditions. Partnering with reputable manufacturers provides assurance of reliability and compliance with international standards, cementing FRP as a trusted solution in various industrial settings. In conclusion, the choice of FRP tanks and vessels is a testament to intelligent decision-making in industrial applications. Their corrosion resistance, customization potential, environmental considerations, and rigorous quality checks make them a preferred choice for businesses aiming to optimize storage and processing capabilities. As we continue to advance technologically and environmentally, FRP solutions will undoubtedly remain at the forefront, underscoring the importance of experience, expertise, authoritativeness, and trustworthiness in industrial product selections.

Further establishing FRP's authoritative stance in the product market is its environmentally friendly nature. Sustainability is becoming a critical concern across industries, and FRP tanks and vessels address this need with their energy-efficient production processes and long-term usability. They contribute to a reduced carbon footprint, aligning with global environmental goals while maintaining top-notch industrial standards—a factor that resonates well with environmentally-conscious businesses today. Trustworthiness in FRP tanks and vessels is cemented by rigorous testing and certifications. Every product undergoes stringent quality assessments, from leak tests to pressure tests, ensuring they meet safety regulations and perform under expected operational conditions. Partnering with reputable manufacturers provides assurance of reliability and compliance with international standards, cementing FRP as a trusted solution in various industrial settings. In conclusion, the choice of FRP tanks and vessels is a testament to intelligent decision-making in industrial applications. Their corrosion resistance, customization potential, environmental considerations, and rigorous quality checks make them a preferred choice for businesses aiming to optimize storage and processing capabilities. As we continue to advance technologically and environmentally, FRP solutions will undoubtedly remain at the forefront, underscoring the importance of experience, expertise, authoritativeness, and trustworthiness in industrial product selections.

Share

Latest news

-

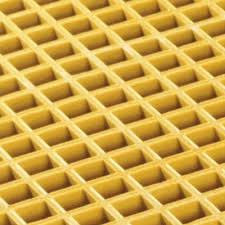

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024