loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Grated Floor Panels for Enhanced Safety and Durability in Various Applications

Understanding Grating Floor Plates A Comprehensive Overview

Grating floor plates, often referred to simply as grating, play a pivotal role in various industrial and commercial applications. These innovative flooring solutions are designed to provide support, safety, and efficiency in environments where traditional flooring options may fall short. This article aims to explore the purpose, benefits, materials, and applications of grating floor plates.

What Are Grating Floor Plates?

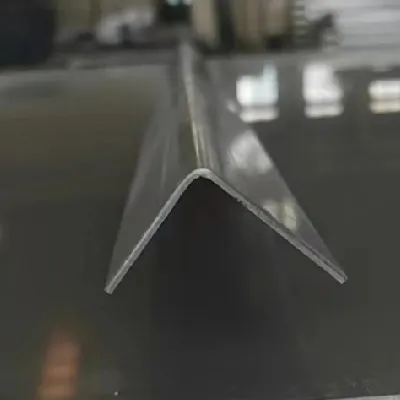

Grating floor plates are structural elements that consist of a series of interconnected bars or mesh, creating a grid-like pattern. This design allows for the free flow of light, air, and liquids, making them ideal for environments where drainage, ventilation, and quick accessibility are essential. Commonly made from materials like steel, fiberglass, or aluminum, grating floor plates can be utilized indoors and outdoors, making them versatile across various settings.

Key Advantages of Grating Floor Plates

1. Safety One of the most significant advantages of grating floor plates is enhancing safety in high-traffic areas. The open design significantly reduces the accumulation of water, oil, and other substances that could lead to slips and falls. Additionally, the non-slip surface treatments available for these plates add an extra layer of safety for workers in industrial settings.

2. Lightweight and Durable Grating floor plates are often lighter than solid flooring alternatives, making them easier to install and maintain. Despite their lightweight nature, they are incredibly durable and can withstand substantial loads, making them suitable for demanding industrial applications.

3. Versatility Grating floor plates can be used in various applications, from factory floors and walkways to platforms and stair treads. They can be easily customized in terms of size, thickness, and bar spacing, allowing for tailored solutions that meet the specific needs of different environments.

4. Drainage and Ventilation The open design facilitates efficient drainage and ventilation. This is particularly advantageous in settings such as food processing plants, chemical facilities, and wastewater treatment plants, where proper drainage can prevent hazardous buildup and contribute to a healthier work environment.

5. Cost-Effective Though the upfront cost of installing grating floor plates can be higher than traditional flooring, their longevity and low maintenance requirements can result in significant savings over time. The durability of materials like steel and fiberglass ensures that these products can withstand harsh conditions without frequent replacement.

Material Options

The choice of material for grating floor plates significantly influences their application and performance

. The most common materials includegrating floor plate

- Steel Known for its strength and longevity, steel grating is widely favored in heavy-duty applications. It can support substantial loads and withstand harsh environmental conditions, making it a go-to choice for industrial settings.

- Fiberglass Fiberglass-reinforced plastic (FRP) grating is advantageous for environments where corrosion resistance is crucial. It is lightweight, non-conductive, and resistant to chemicals, making it suitable for chemical plants and marine applications.

- Aluminum Aluminum grating offers a balance between strength and weight. It resists rust and corrosion, which makes it ideal for outdoor applications, including access platforms and walkways in coastal areas.

Applications of Grating Floor Plates

Grating floor plates are utilized across diverse industries, including

- Manufacturing In manufacturing facilities, grating floor plates provide safe access to machinery and allow for effective drainage in areas prone to spills.

- Chemical Processing In chemical plants, FRP gratings protect against corrosion while ensuring safety through their slip-resistant surfaces and open designs.

- Transportation Grating is often used in transportation sectors to create lightweight platforms for loading and unloading goods without obstructing airflow.

- Marine and Coastal Applications Aluminum and fiberglass gratings are ideal for marine environments where exposure to saltwater can corrode other materials.

Conclusion

Grating floor plates offer an array of benefits, from enhancing safety to improving efficiency in various environments. Their versatility, combined with the durability of materials like steel, fiberglass, and aluminum, makes them suitable for a wide range of applications. As industries continue to evolve and prioritize safety and functionality, grating floor plates will remain integral to modern design and construction practices. By understanding the characteristics and applications of grating, businesses can make informed decisions that enhance their operational effectiveness and workplace safety.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024