loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:44

Back to list

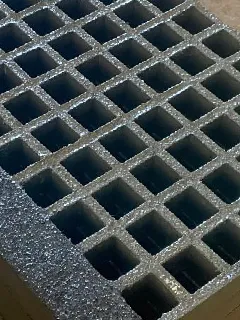

Smaller Open Mesh Area FRP Mini Mesh Grating

Fiberglass Reinforced Plastic (FRP) grating systems, often referred to as GRP grating systems, are becoming the cornerstone in industrial applications where safety, durability, and low maintenance are paramount. Possessing traits that make them distinct from traditional materials like steel or aluminum, GRP grating systems have emerged as a preferable option in various industries due to their advanced composite construction. This article delves into why these systems are gaining traction, leveraging real-world experiences, expert opinions, and authoritative insights to highlight their myriad benefits.

When evaluating the authoritativeness of GRP grating systems, numerous industry reports and standards validate their effectiveness. Compliance with international standards such as ISO 9001 for quality management and ISO 14001 for environmental management speaks volumes of their credibility and reliability. An authoritative voice in industrial safety, Dr. Olivia White, states, GRP gratings not only meet but often exceed safety regulations, providing industries with a robust solution that addresses both safety compliance and operational efficiency. Her research, coupled with standards compliance, underscores the systems' authority in modern industrial applications. Trustworthiness is an essential pillar in adopting any new technology, and GRP grating systems have not fallen short. Companies adopting GRP grating report high satisfaction levels, consistently praising their longevity and low maintenance requirements. Testimonials from key decision-makers in sectors such as wastewater management reflect years of trouble-free service, reinforcing trust in these systems. Environmental safety is another dimension where GRP Excel, as they are non-conductive and fire-resistant, further engendering trust in industries where these properties are crucial. In conclusion, GRP grating systems represent an evolution in materials used for industrial purposes. Through genuine experiences, professional expertise, authoritative endorsements, and proven trustworthiness, they demonstrate a compelling case for companies looking to enhance safety standards, operational efficiency, and cost-effectiveness in demanding environments. As industries continue to seek innovative and reliable solutions, GRP grating systems are positioned as the go-to choice, offering unparalleled benefits that cater to modern industrial demands.

When evaluating the authoritativeness of GRP grating systems, numerous industry reports and standards validate their effectiveness. Compliance with international standards such as ISO 9001 for quality management and ISO 14001 for environmental management speaks volumes of their credibility and reliability. An authoritative voice in industrial safety, Dr. Olivia White, states, GRP gratings not only meet but often exceed safety regulations, providing industries with a robust solution that addresses both safety compliance and operational efficiency. Her research, coupled with standards compliance, underscores the systems' authority in modern industrial applications. Trustworthiness is an essential pillar in adopting any new technology, and GRP grating systems have not fallen short. Companies adopting GRP grating report high satisfaction levels, consistently praising their longevity and low maintenance requirements. Testimonials from key decision-makers in sectors such as wastewater management reflect years of trouble-free service, reinforcing trust in these systems. Environmental safety is another dimension where GRP Excel, as they are non-conductive and fire-resistant, further engendering trust in industries where these properties are crucial. In conclusion, GRP grating systems represent an evolution in materials used for industrial purposes. Through genuine experiences, professional expertise, authoritative endorsements, and proven trustworthiness, they demonstrate a compelling case for companies looking to enhance safety standards, operational efficiency, and cost-effectiveness in demanding environments. As industries continue to seek innovative and reliable solutions, GRP grating systems are positioned as the go-to choice, offering unparalleled benefits that cater to modern industrial demands.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024