loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

grp structures

Understanding GRP Structures A Comprehensive Overview

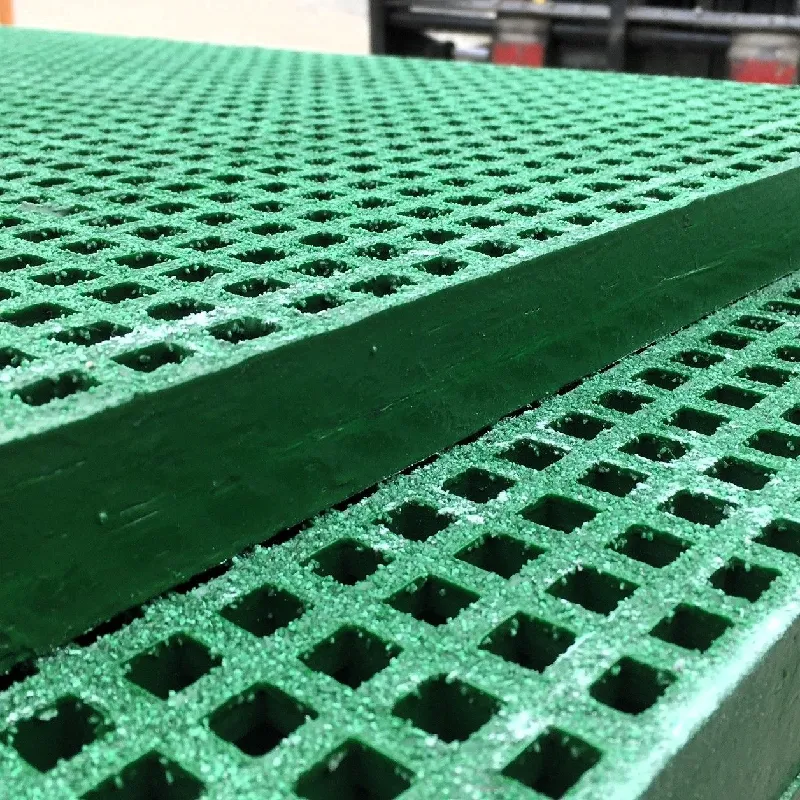

Glass Reinforced Plastic (GRP) structures have become a fundamental aspect of modern engineering and construction, offering superior performance in various applications. GRP, also commonly known as Fiber Reinforced Plastic (FRP), is a composite material made of a polymer matrix reinforced with glass fibers. This innovative material combines the benefits of high strength-to-weight ratio, corrosion resistance, and versatility, making it an ideal choice for a range of applications across multiple industries.

Understanding GRP Structures A Comprehensive Overview

Moreover, GRP structures are inherently resistant to corrosion, which further extends their lifespan and reduces maintenance costs. Unlike traditional materials such as steel and aluminum, GRP does not rust or corrode when exposed to moisture and chemicals, making it an excellent choice for applications in chemical processing plants or coastal regions. This characteristic not only ensures longevity but also contributes to the overall sustainability of projects, as the need for frequent replacements and repairs can be minimized.

grp structures

Another compelling aspect of GRP structures is their lightweight nature. The low density of glass fibers compared to metals leads to structures that are significantly lighter while still maintaining structural integrity. This property allows for easier handling, transportation, and installation, which can lead to reduced labor costs and shorter project timelines. The lightweight nature of GRP also minimizes the demand on supporting structures, allowing for innovative architectural designs that would be impractical with heavier materials.

In terms of versatility, GRP can be tailored to meet specific requirements through various manufacturing processes, including hand lay-up, spray-up, and pultrusion. This adaptability allows engineers and designers to create complex shapes and forms that meet the distinct needs of their projects. Furthermore, GRP can be easily molded into different colors and finishes, providing aesthetic value alongside functionality.

Despite its advantages, there are considerations to be aware of when working with GRP structures. The initial cost can sometimes be higher than traditional materials; however, the long-term benefits, such as reduced maintenance and extended service life, often justify this investment. Additionally, while GRP itself is resistant to many environmental factors, it is essential to employ appropriate bonding and joining techniques to ensure the integrity of larger structures.

In conclusion, GRP structures represent a significant advancement in material technology, offering a unique blend of strength, durability, and versatility. As industries continue to seek sustainable and efficient solutions, the adoption of GRP is likely to increase. Understanding the properties and applications of GRP can empower engineers and architects to utilize this remarkable material effectively, leading to innovative designs and enhanced performance in various sectors. As we move forward, the potential of GRP as a cornerstone of modern construction and manufacturing becomes increasingly evident, paving the way for a more resilient and sustainable future.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024